First megawatt-class AEM Electrolyser will boost green H2 rollout and introduce modular electrolysis on a grander scale

SAERBECK, Germany — Enapter is expanding its product portfolio to the megawatt-class with the AEM Multicore electrolyser. The final development of the new model has started, further tapping into the innovative potential of Anion Exchange Membrane (AEM) technology. The AEM Multicore will be introduced to the market next year, enabling low-cost, flexible and reliable green hydrogen production. Orders are now open.

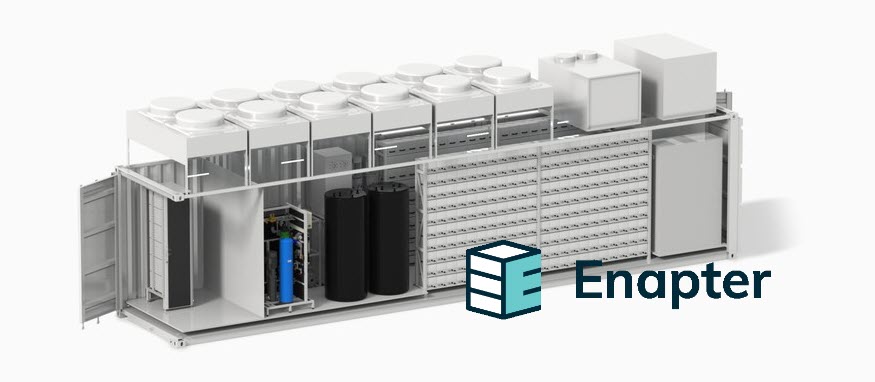

As the AEM electrolysis technology leader, Enapter will cut the cost of green hydrogen by mass-producing standardised products. The AEM Multicore is no exception: It will feature 440 mass-produced electrolyser core modules – the “AEM stacks” – in a complete system that can produce ~450 kg of hydrogen per day. This is the energy equivalent of around 9.5 barrels of crude oil. With this modular approach, it offers a lower-cost alternative to traditional megawatt-class electrolysers while also proving highly responsive to the fluctuations of renewable electricity supply.

“The AEM Multicore will be cheaper than comparable PEM electrolysers and using mass-produced AEM stack modules makes the difference,” says Sebastian-Justus Schmidt, Chairman of Enapter AG. “The modular approach makes the entire system more affordable but also significantly more robust and enormously flexible. This makes it ideal for using intermittent renewable energy.”

Its multi-core approach also offers reliability advantages compared to conventional systems. If one stack module fails, it can be replaced in a few simple steps, while the “balance of plant” system that supports hydrogen production also has built-in redundancy. Its unique modularity allows the AEM Multicore to flexibly adjust production levels in reaction to changes in renewable energy supply.

AEM is widely considered by scientists to be the most cost-efficient electrolysis technology. Enapter is getting closer to realising AEM’s full potential to accelerate the adoption of green hydrogen energy, with construction of its “Campus” mass-production facility in Saerbeck set to begin in autumn this year – and planned to reach completion and operation in 2022. With this, the AEM Multicore will be ready to make a substantial contribution to the rapid scale-up of electrolyser capacity, the demand for which is reflected in targets such as the 5 GW in installed generation capacity Germany is calling for by 2025. With the Campus’s foreseen annual production capacity of 280 MW, it could meet more than 5% of this goal each year.

Contact our team to enquire about orders here.

Read the most up to date Fuel Cell and Hydrogen Industry news at FuelCellsWorks