- Highly efficient electrodes makes green hydrogen even greener

Green hydrogen produced by alkaline electrolysis is predicted to play an essential role in the future CO2-neutral society. It is also crucial for the green conversion of Europe’s energy systems. HydrogenPro’s new research project will optimise the process and bring our electrode technology into the lead.

ÅRHUS/PORSGRUNN– HydrogenPro Denmark has joined forces with Danish Technological Institute and Aarhus University to super-optimize this process. This project, which has the name LC-H2, is co-financed by the Innovation Fund with NOK 15,4 million. The project’s total budget is NOK 22 million and runs over the next three years.

– The hydrogen industry is flourishing right now, and therefore with this project, we want to develop the next generation of highly efficient electrodes that will make the electrolysis process as energy-efficient as possible. There is no doubt that the project here is a milestone in alkaline electrolysis, says Lars Pleth Nielsen, CEO of HydrogenPro Denmark, who leads the project.

The potential is enormous. This project will ensure HydrogenPro’s competitiveness as a world-leading technology provider and solutions for the large-scale production of green hydrogen.

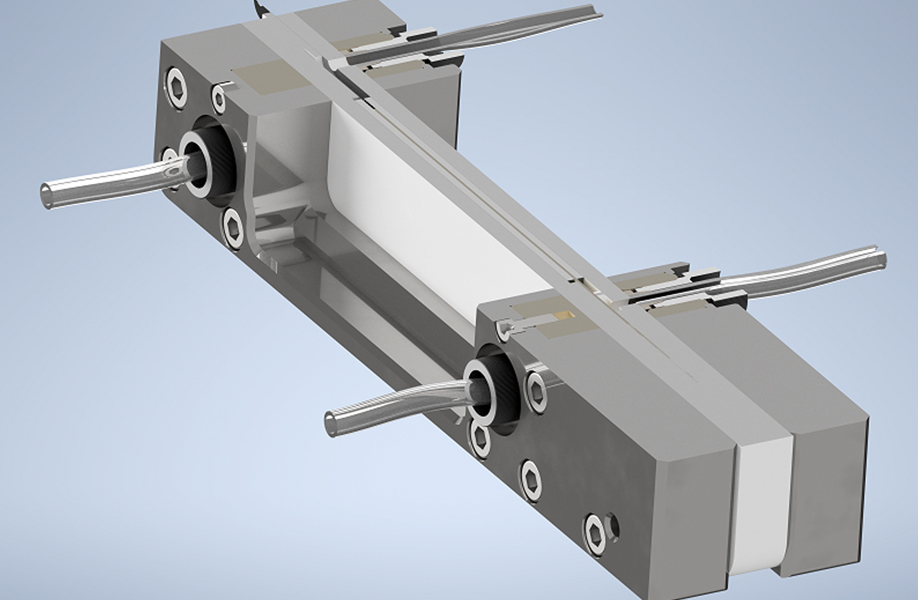

The electrolysis process uses two electrodes, a cathode, and an anode, which split water into hydrogen and oxygen via direct current. The modern hydrogen industry uses highly developed, porous electrodes with the largest possible surface area for hydrogen production to optimise reaction area and production volume.

Unknown process

Hydrogen and oxygen form bubbles in the water, which appear to be the process’s main product. But, when formed in excess, they limit the efficiency of the process, as the bubbles create increased resistance.

However, the details of this process are still relatively unknown: You know how much power you put into the process and how much hydrogen you get out, but exactly what takes place in the electrolysis cell during hydrogen formation and which parameters can be adjusted to optimise the process, still needs to be discovered.

The LC-H2 project is based on HydrogenPro’s existing electrode technologies, combined with high-resolution numerical simulations, tests and analyses, and neutron photography of hydrogen formation.

Read the most up to date Fuel Cell and Hydrogen Industry news at FuelCellsWorks