La Motte-Fanjas–McPhy (Euronext Paris Compartiment C: MCPHY, FR0011742329), specialized in hydrogen production and distribution equipment, today announced having been selected to deploy two stations with a capacity of 400 kg of hydrogen per day each, connected to a 1 MW high-power electrolyzer, on the territory of Dijon Métropole.

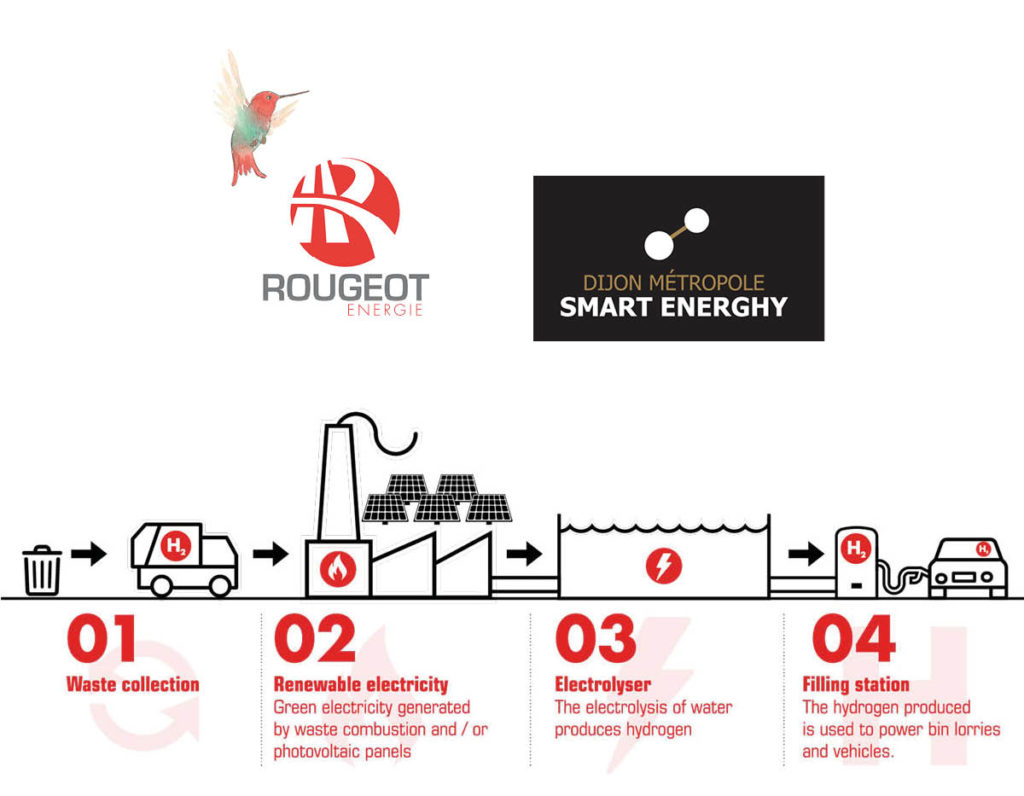

• ROUGEOT Energie, operating as general contractor EPC (1) on behalf of Dijon Métropole Smart EnergHy, has selected McPhy’s hydrogen production, compression and distribution solution to supply the metropolitan fleet of heavy (buses, garbage trucks) and light (utility and passenger cars) vehicles.

• McPhy will design, build and integrate two hydrogen stations with a capacity of 400 kg of hydrogen per day each, connected to a 1 MW high-power electrolyzer, for a complete zero-emission mobility chain.

• Following the signature of this new contract totaling more than €4 million, McPhy’s references reach a total of 33 stations and 43 MW of high-power electrolysis (2).

“The project supported by Dijon Métropole Smart EnergHy contributes to the democratization of hydrogen as a zero-emission alternative for public, professional or private transport. Our stations will make it possible to supply all the hydrogen mobility in the region: buses, garbage trucks, utility and private vehicles. Buses, for example, will be able to refuel with hydrogen produced on site, from household waste or local renewable energies, and travel more than 300 km without emitting any CO2 or polluting particles. More than ever, we are convinced that hydrogen has a decisive role to play in the fight against air pollution and climate change.”, testified Laurent Carme, CEO of McPhy.

Dijon Métropole is implementing a complete zero-emission hydrogen ecosystem

To promote and develop its hydrogen infrastructure, Dijon Métropole has created, with ROUGEOT Energie, the project company Dijon Métropole Smart EnergHy (DMSE).

The first step of the deployment plan is to implement, in the north of Dijon, a McPhy hydrogen solution composed of two hydrogen stations, coupled with on-site hydrogen production.

Four distribution terminals for both heavy and light vehicles will thus be available to supply the zero-emission vehicles of the collectivity and its partners. This fleet of hydrogen vehicles will initially be made up of 27 buses, 9 garbage trucks and around 15 light vehicles. The project is expected to reach a total of 200 buses, 50 garbage trucks and 250 light vehicles by 2030.

This project stands out for the positive energy loop it will create in the heart of the Dijon metropolitan area. The electrolyzer connected to produce hydrogen on site will be powered 90% by electricity from a household waste incinerator and the remaining 10% will come from locally produced renewable energies. Consequently, the “Dijon Nord” project will enable the recovery of so-called “fatal” electricity, which would have been lost if it had not been used to power this ecosystem, and avoid nearly 2,500 tons of CO2 emissions per year (3).

The “Dijon Nord” project has received support and co-financing from the French Environment and Energy Management Agency (ADEME).

With many references already installed in the territories, McPhy has been selected by ROUGEOT Energie, acting as general contractor on behalf of the company DMSE, to design, manufacture and commission a complete chain of zero-emission hydrogen mobility. Two McFilling hydrogen stations, one offering a filling pressure of 350 bar and the other offering a “Dual Pressure” configuration (350 and 700 bar), will ensure, thanks to a very high availability rate and a total daily potential of 800 kg of hydrogen delivered, the continuity of public services and the refueling of professional and private vehicles in the area. Indeed, the solution proposed by McPhy offers a fast recharging time, around a few minutes, and the possibility of simultaneous recharging, thanks to the redundancy of the equipment, which boosts the capacity of the stations in case of peak consumption.

Interfaced with the hydrogen stations, the McLyzer electrolyzer will have a production capacity equivalent to 1 MW of high-power electrolysis and will be equipped with high current density electrodes, ensuring optimal performance and energy efficiency to complete this hydrogen production and distribution ecosystem.

This new contract, totaling more than €4 million, brings McPhy’s references to 33 stations and 43 MW of high-power electrolysis and confirms the Group’s position as a strategic partner for zero-emission mobility projects.

Footnotes

(1) EPC: “engineering procurement and construction”

(2) References already deployed, under installation or in development. Among them, 2 HRS and 4 MW ELY are part of the conditional part of the Zero Emission Valley framework agreement, signed on June 2020.

(3) Source: JUSTY engineering office

Read the most up to date Fuel Cell and Hydrogen Industry news at FuelCellsWorks