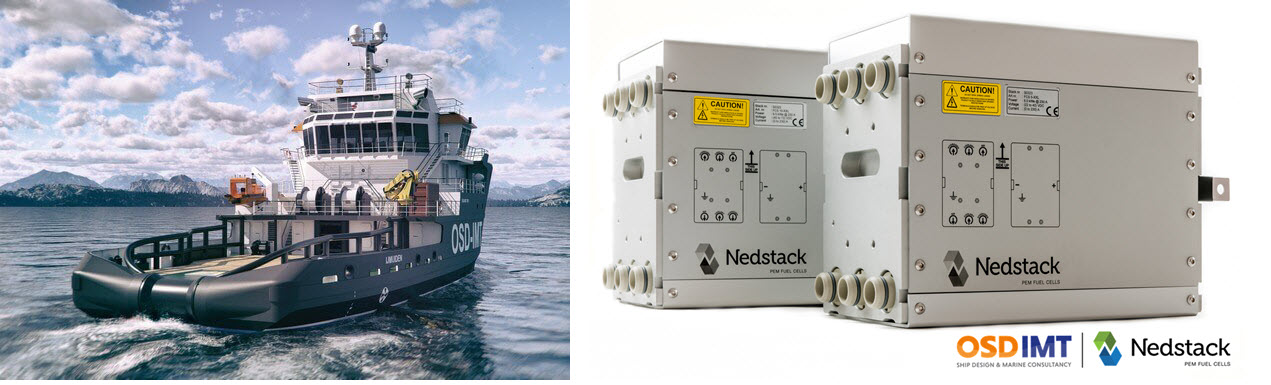

Ship design and marine consultancy firm OSD-IMT and PEM Fuel Cell Market Leader Nedstack have joined to develop a concept design for a 65 tonnes bollard pull harbour tug, fully electric driven.

The electric power for the propulsion motors is generated onboard by hydrogen fuel cells, creating a totally emission free tug. No CO2, no NOx, no Sulphur, no PM will come from the tug. The only effluent is water!

Why?

Reduction of emissions is a widely recognized issue and especially in industrial areas like harbours and ports, often situated in urban surroundings, efforts must be made to reduce the environmental footprint of economic activity. The constant presence of tugs in these environments make it inevitable for them to also reduce their footprint. In addition, with their local operations, high power and limited sailing times, tugs form an excellent platform for testing and scaling of new developments and technology.

Challenges?

Of course, the main challenge is the storage of hydrogen on board. It falls into two parts; one is the safety of crew, assets and environment, the other is the energy capacity. The capacity of the storage defines the endurance of the vessel. Several routes are being investigated on a global scale, on the physical side covering things such as pressurization and liquefaction, but also on the material side where hydrogen is bonded and released to other materials for storage. As with all new technology, rules and regulations are still being developed. Both OSD-IMT and Nedstack are following the developments closely and make sure that regulations are implemented into the design of the installation and vessel design.

The result?

The result is an ASD-based concept design with three men crew facilities. It generates 65 tonnes bollard pull from twin azimuth thrusters and the single winch concept makes it suitable for operations both astern and over the bow. The hydrogen is stored in quickly and safely exchangeable 20ft ISO containers, providing a 2-4 day endurance in normal harbour operations.

What’s next?

This design is intended to be scalable to larger and smaller tugs and likewise the performance. Before the end of 2019 a concept design for a 45-50 tonnes bollard pull tug will be developed. By mid-2020 OSD-IMT expects to also have a concept for a 75-80 tonnes bollard pull tug in its portfolio.

Read the most up to date Fuel Cell and Hydrogen Industry news at FuelCellsWorks