- The company has participated in the first project of the Ceramic Technology Institute to replace natural gas with hydrogen in ceramic kilns.

- Air Products has supplied the hydrogen that has proven its efficiency in combustion mixed with natural gas in the test furnace.

Carburos Metálicos, a leading company in the industrial and medical gases sector in Spain that is part of the Air Products Group, has successfully concluded its participation in a pioneering initiative to accompany the ceramic and glass manufacturing industry on its path to decarbonization , in line with the national and European objectives that set the year 2050 as the deadline to achieve an economy with a neutral balance in CO2 emissions.

One of the alternatives available to the ceramic sector to advance towards this objective is the transition to mixtures of natural gas and hydrogen in ceramic tile firing kilns, as well as in frit melting kilns. The Institute of Ceramic Technology (ITC-AICE) of Castellón, a reference in this field in Spain, leads a study that is part of the project called ‘Experimental study on a laboratory scale of ceramic firing using hydrogen as fuel (Hidroker) ‘. Said study, financed by the Generalitat Valenciana through the Valencian Institute of Business Competitiveness (IVACE), focuses on the use of hydrogen as a direct source of thermal energy by combustion in the drying and cooking processes.

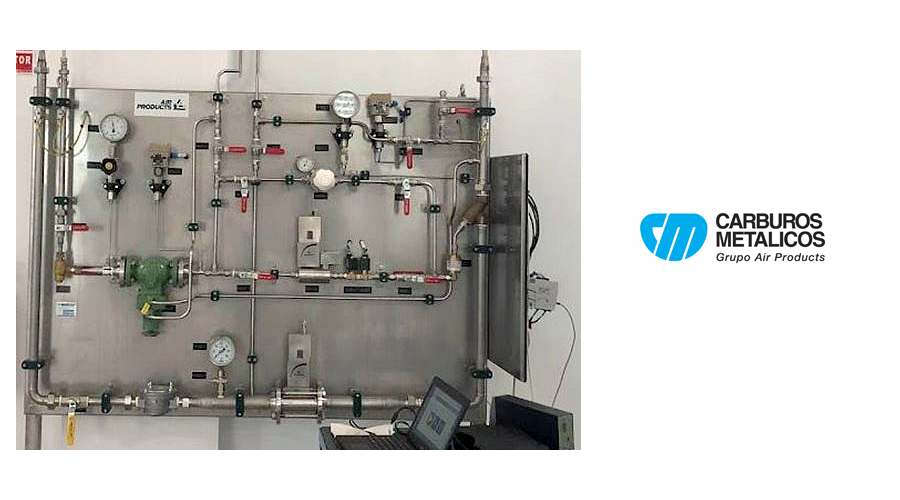

The Air Products and Air Products combustion team has been in charge of providing the mixing panel and the precise combination of natural gas and hydrogen that has helped achieve controlled combustion with conventional burners and up to 20% hydrogen, a whole milestone in the ceramic industry. Over several decades, Air Products has accumulated a wealth of experience in supplying hydrogen to different industries and has been developing technologies and products for these segments for more than 30 years.

Pioneering and successful trial

This experience accumulated by the group has proven to be very valuable for accompanying companies in the ceramic sector in Spain in their goal of gradually replacing natural gas with hydrogen and thereby reducing their CO2 emissions. In this sense, the test in which technicians from Carburos Metálicos and Air Products have collaborated is even more important, since it was the first time that the ITC used hydrogen in a ceramic kiln.

The Air Products and Air Products team has provided the hydrogen mixing panel and the precise combination of natural gas and hydrogen that has contributed to achieving controlled combustion with conventional burners with up to 20% hydrogen, a milestone in the ceramic industry . The immediate objective is to prolong this collaboration with the ITC in such a way that higher percentages of hydrogen are achieved, which will require, in turn, the adaptation of current combustion systems and burners, with an eye toward achieving 100% this gas in the near future.

Air Product technology to reduce CO2 emissions

Air Products has successfully developed and tested burners that use up to 100% hydrogen and both air and oxygen as oxidants. The know-how from these developments, coupled with decades of experience in the production, handling and distribution of hydrogen, have contributed to the success of the tests at ITC.

Other industries, such as metallurgy, glass and frits, can also benefit from the systems created by the Group to improve their quality and sustainability. The industry is currently in the first phases of testing hydrogen in its processes, a transition to this element that still involves the use of small volumes, but that will allow acquiring experience in handling hydrogen and, therefore, optimizing the tools , technologies and procedures to adopt the use of 100% hydrogen as a fuel in a safe, efficient and economical way. In fact, this could be the most promising path towards decarbonization of the glass industry.

The Air Products group also has a significant portfolio of technologies and operational experience in oxygen-enhanced combustion, from which these industries can equally benefit. This process relies on oxygen enrichment or flame cutting to improve the efficiency and productivity of heating and melting furnaces. By moving from the traditional ‘air-fuel’ combustion system to an ‘oxy-fuel’ one, it has been shown that the energy required can be reduced by up to 40%, which in turn can translate into 40% less direct greenhouse gas emissions. CO2, among other pollutants generated by these processes. The reason is that the use of pure oxygen (instead of air) is more efficient, since the fuel reacts much faster with oxygen, and that increases the temperature of the flame up to about 1,000°C. Air Products’ oxy-fuel burners also support the combustion of natural gas and hydrogen mixtures, offering a direct path to reducing carbon footprint without generating higher ceramic kiln wall temperatures, elevated carbon oxide emissions, nitrogen or inefficiencies in the glass melting process.

On the other hand, the company is working on reducing CO2 emissions generated by the production and transport of oxygen, making it possible to make this a ‘green’ or renewable oxygen.

“The ceramic sector is intensive in the use of thermal energy and the margin for reducing direct emissions from its production processes is certainly limited if it does not substantially modify the technologies and energy sources it uses. The research led by the Institute of Ceramic Technology represents a first step to incorporate hydrogen into this industry, a molecule of great interest to achieve the planned decarbonisation objectives”, explains Dr. Salvador Ferrer, from the ITC Sustainability Area.

“At Carburos Metálicos we have the experience and technology of the Air Products group that covers, among other areas, the entire hydrogen value chain. We are working on the development of new solutions and technologies to support the ceramic, frit and glass industry in its decarbonization goals. Contributing to achieving low-carbon combustion using hydrogen mixtures has been a very important step that we are very proud of”, commented Miquel Lope, general director of Carburos Metálicos.

About Carburos Metálicos,

Carburos Metálicos is a leading company in the industrial and medical gases sector that produces, distributes and sells gases for multiple sectors: metallurgy, glass, water, food, medicine, energy, petrochemicals, laboratories, freezing, refrigeration, oenology, leisure and beverages. . The company provides a wide range of products, solutions and services to its customers, as well as materials and equipment for the applications of these gases.

Founded in 1897, Carburos Metálicos has been serving the industry in our country for more than 120 years and has always maintained a strong bond with society. Currently, it is the leader in the industrial and medical gases sector in Spain and a benchmark in the chemical sector in matters of safety, innovation and sustainability.

Carburos Metálicos has a team of more than 700 professionals in Spain, a daily production capacity of more than 1,200 tons of liquefied gas (mtpd), 12 production plants, 14 bottling plants, 2 high-purity gas laboratories and a R&D center located in Bellaterra (Barcelona) serving more than 100,000 customers. Since 1995, the company has belonged to the US group Air Products (NYSE:APD). Visit www.carburos.com

Sobre Air Products

Air Products is one of the world’s leading industrial gases companies, where it has been operating for 80 years. The company supplies industrial gases and the necessary equipment to dozens of productive sectors, including the refining and petrochemical, metallurgical, electronic components or food and beverage industries. Air Products is also the world’s leading provider of liquefied natural gas equipment and technology. It also develops some of the world’s largest gasification, CO2 capture and carbon-free hydrogen projects to promote mobility and the energy transition.

The group recorded sales of $10.3 billion in 2021 from its activities in more than 50 countries and currently has a market capitalization of around $55 billion. More than 20,000 passionate, committed and talented employees from diverse backgrounds are guided by Air Products’ ultimate goal of creating innovative solutions that benefit the environment, improve sustainability and address the challenges facing customers, communities and the world.

Image: Carburos Metalicos

Read the most up to date Fuel Cell and Hydrogen Industry news at FuelCellsWorks