- Multiple connections allow a higher output, while the output adjustment function enables flexible power generation plans

Osaka, Japan – Panasonic Corporation (hereinafter referred to as Panasonic) today announced that its Electric Works Company will launch a new pure hydrogen fuel cell generator that generates power through a chemical reaction between high-purity hydrogen and oxygen in the air in Oct. 2024 in Europe*1, Australia, and China.

In October 2021, Panasonic launched a 5-kW type pure hydrogen fuel cell generator PH1 (single-phase three-wire type). The company will now launch a new product PH3 (DC type) for overseas markets to fully scale up its hydrogen business outside Japan.

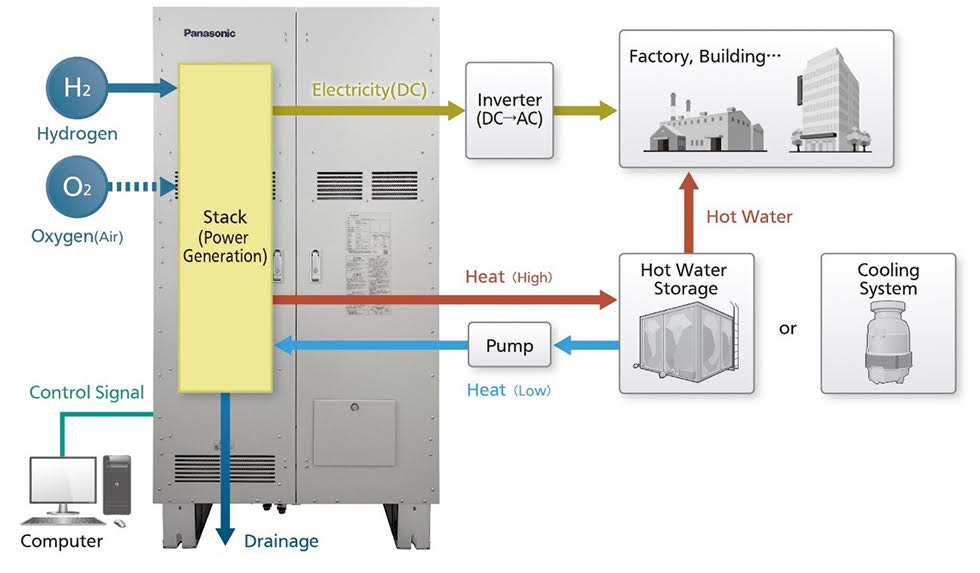

Since the PH3 to be launched is a cogeneration system, it can output a maximum of 10 kW of DC power, and generate approximately 8.2 kW of heat, which can be used to heat water to approximately 60ºC. The product is designed to output DC power in order to support power voltage in a wide variety of countries and areas.

In addition to a higher output by connecting multiple units (up to 250 modules), the power output can be adjusted*2, allowing for the formulation of flexible power generation plans.

Furthermore, maintenance access points are located in the front, and the product is designed to withstand cold temperatures, as well as high altitudes, enabling it to be proposed to customers with various installation environments.

In addition, the product achieves an electrical efficiency of 57% (DC, LHV), heat recovery efficiency of 47% (LHV), and a total efficiency of 104%*3, contributing to reduced running costs. The overhaul stop period is designed to be 15 years to ensure a long operating life*4, which can reduce life cycle costs.

Panasonic, based on knowledge obtained through H2 KIBOU FIELD*5,6, the demonstration facility for RE100 solutions in Japan, plans to carry out similar demonstrations in its own factories in Wales, as well as in Germany.

Panasonic will offer a new option, full-scale use of hydrogen, in order to expand the introduction of renewable energy based on the Panasonic GREEN IMPACT formulated by the Group, contributing to the realization of a decarbonized society.

*1: The planned target markets are Germany, the UK, Belgium, Switzerland, France, Austria, Netherlands, Spain, and Italy.

*2: Power output can be set in 1 kW increments between 4 kW and 10 kW per module.

*3: The new product can recover condensation latent heat. Since its heat recovery rate includes condensation latent heat, its total efficiency is over 100%.

*4: The operating life is depended on customer’s power generation plan. (Whichever comes first energization time 15 years, cumulative hours of power generation 100,000 hours and cumulative start & stop cycle 4,500 times)

*5: The H2 KIBOU and H2 KIBOU logos have been registered as trademarks of Panasonic Corporation.

*6: In April 2022, Panasonic began operations at its RE100 solution demonstration facility in Japan, which generates 100% of the power used by its fuel cell factory from renewable resources using a self-sustaining power system that combines generation from both pure hydrogen fuel cell generators and photovoltaic generators. As a result, high environmental performance (a power purchase reduction rate of 98%) was achieved. Although hydrogen from renewable energy is not used during demonstration, Panasonic aims for the achievement of RE100 by using hydrogen derived from renewable energy in the future.

Main Features

- Cogeneration system with a maximum 10 kW of DC power output

- Multiple 10 kW modules can be connected. Furthermore, the output adjustment function*2enables more flexible power generation plans.

- Highly-flexible installation facilitates proposals to a wide range of customers

- High efficiency and long-designed life cycle reduce total costs

- Cogeneration system with a maximum 10 kW of DC power output

A pure hydrogen fuel cell generator PH3 can generate a maximum of 10 kW of DC power, as well as approximately 8.2 kW of heat through a chemical reaction between high-purity hydrogen and oxygen in the air. By connecting a hot water storage to the product, heat generated from the fuel cell can be converted into hot water (approx. 60ºC) for use in a factory or building.

- Multiple 10 kW modules can be connected. Furthermore, the output adjustment function*2enables more flexible power generation plans.

By using the dedicated PH3 app, the power output can be adjusted in 1 kW increments between 4 kW and 10 kW per module.

Since up to 250 pure hydrogen fuel cell generators can be connected, flexible power generation plans can be formulated for factories and buildings where various types of demand fluctuations are expected.

- Highly-flexible installation facilitates proposals to a wide range of customers

The PH3 can be installed even in small spaces, since the maintenance access points are located in the front*7.

It can also be provided to a wide range of customers as it is resistant to cold (lower limit: -15ºC), as well as high altitude (1,000 m).

*7: Since installation regulations differ depending on the country, please confirm them before installation.

- High efficiency and long-designed life cycle reduce total costs

High efficiency rates such as an electrical efficiency of 57% (DC, LHV), heat recovery efficiency of 47% (LHV), and total efficiency of 104% have been achieved. High efficiency leads to reduced hydrogen usage, contributing to reduced running costs. The overhaul stop period is designed to be 15 years to ensure a long operating life*4, which can reduce life cycle costs.

Specifications

| PH3 (DC type) |

|||

| Product name | Pure Hydrogen Fuel Cell Generator “H2 KIBOU” | ||

| Type of fuel cell | Polymer Electrolyte Fuel Cell (PEFC) | ||

| Model number | FC-H99PGD1P | ||

| Year and month of launch | October 2024 (planned) | ||

| Design panel | Optional product (separately sold) | ||

| Configuration | Cogeneration system (external water-cooling system) | ||

| Basic performance | Output | Power | 10 kW max. Adjustable in 1 kW increments between 4 and 10 kW |

| Voltage | DC 380-495 V*8 (Fixed Voltage) |

||

| Power consumption | During startup | 300±90 W | |

| Freezing prevention | 583 W | ||

| Efficiency | Power generation (DC) | LHV: 57%, HHV: 48.1% | |

| Heat recovery | LHV: 47%, HHV: 39.7% | ||

| Hydrogen | Consumption | 97.5 NL/min ≈ 6 Nm3/h | |

| 103.7 NL/min (Max) | |||

| Supply pressure | 50±20 kPa | ||

| Exhaust heat | Output | 8,248 W | |

| Water-cooling device | Water-cooling equipment is required (external procurement) |

||

| Supporting cogeneration | Hot water storage unit (external procurement) | ||

| Time | Startup | 30 sec (approx. 40 sec to achieve the rating) | |

| Continuous power generation | 168 hours (7 days) | ||

| Dimensions | Main unit | W900 mm x D865 mm x H1,787 mm

W900 mm x D898 mm x H1,787 mm (with a design panel) |

|

| Main unit packaging | W957 mm x D966 mm x H1,917 mm | ||

| Weight | Main unit when dry | 340 kg 354 kg (with a design panel) |

|

| Packaging when dry | 360 kg (a design panel is 18 kg) |

||

| Control | When up to 10 modules are connected*9 | PH3 app (provided with PH3) (PH3 app is not required during EMS connection) |

|

| When up to 250 modules are connected (with PLC)*10 | |||

| Installation conditions | Maximum altitude for installation | 1,000 m | |

| Maintenance space | Front maintenance: 600 mm, Other: 10 mm *11,12 | ||

| Installation environment temperature | -15 to 40ºC | ||

| Maintenance | Periodical Maintenance | Required depending on cumulative hours of power generation | |

| Overhaul (Whichever comes first) |

Energization time 15 years

Cumulative hours of power generation 100,000 H Cumulative start & stop cycle 4,500 times |

||

*8: The inverter is required conforming to the application note.

*9: The computer used to install the app must be provided by the customer. The computer and fuel cell unit must be connected via LAN.

*10: The computer and PLC used to install the app must be provided by the customer. The computer and PLC, as well as the PLC and fuel cell unit, must be connected via LAN (hub relay).

*11 : On the side of the front face of the main unit, 400 mm space is required to open the door.

*12 : In case of attaching a design panel, 70 mm space is required for left and right sides.

Read the most up to date Fuel Cell and Hydrogen Industry news at FuelCellsWorks