In January 2023, the Vinnova-funded project launched with the objective of developing the first z.truded® bipolar fuel cell plate. The project has made significant progress and is on track to deliver a highly competitive plate alternative for the fuel cell industry by the end of 2023.

Market fit

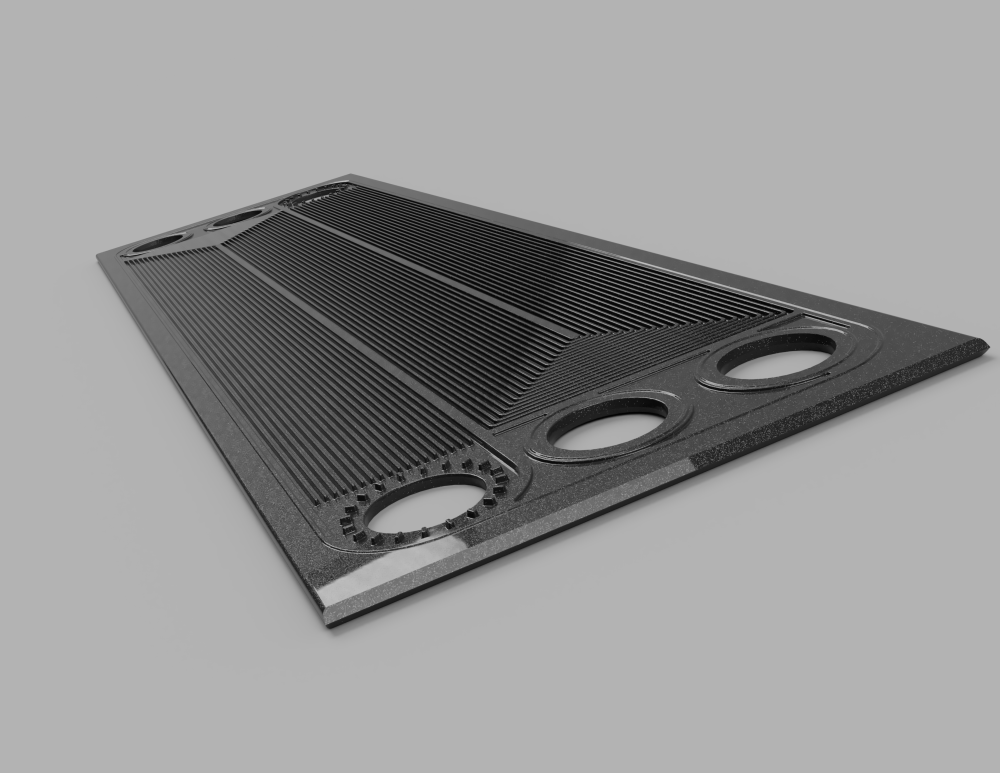

The project aims to fill a gap in the market, and z.trusion® is undergoing this project to realize an offering towards the market of flow plates with design freedom. This means, for example, that unique flow patterns can be designed on both sides of the fuel cell plate, and on top of that, the both sides can be efficiently manufactured in one production step.

Unique flow patterns on both sides of the fuel cell plate, manufactured in one step.

Technical progress

Technical progress has been made in identifying the relevant specifications required to achieve cost-efficient, sustainable z.truded® bipolar fuel cell plates. After conducting thorough research, a voltage of 0.7 volts per plate is assumed and generation of 35 watts of power per plate. The simulation method in place is computational fluid dynamics (CFD) simulations as it gives us the capability to design flow channels on the gas and cooling sides of the plates.

Material

The current focus is on gathering specifications for materials with excellent electrical and thermal properties to ensure the function of the product. This far into the project, we maintain significantly optimistic about a polymer-base with carbon powder filler which so far have been the best-fitting material combination meeting our criteria. Further on, we will use our experience from other projects where we use recycled plastic.

Method

The production method used in the project differs from the commonly used methods, such as hot compression and injection molding, to produce bipolar fuel cell plates. The z.truded® production technique enables high-volume production while ensuring that the product can withstand corrosive environments for long-term usage.

SOURCE: My New Desk

Read the most up to date Fuel Cell and Hydrogen Industry news at FuelCellsWorks