CALGARY, Alberta — Acceleware Ltd. (“Acceleware” or the “Company”), Acceleware is pleased to announce that following six months of operation of its Clean Tech Inverter (“CTI”) at the commercial-scale RF XL pilot project at Marwayne, Alberta, (the “Pilot”), the Company is now working to develop new CTI industrial heating applications via collaborative partnerships. This effort commences with a collaboration between Acceleware and Aurora Hydrogen Inc. (“Aurora”) to produce CTI-powered clean hydrogen via methane pyrolysis. The collaborative nature of Acceleware’s CTI expansion strategy allows the Company to maintain continued focus on the successful execution of the Pilot and the subsequent commercialization of RF XL technology, while also leveraging the power of its CTI for other high value use cases.

With the intent of significantly accelerating time to commercialization for an exceptionally competitive clean hydrogen product, the Acceleware and Aurora collaboration effort will aim to demonstrate efficiency improvements resulting from the use of Acceleware’s proprietary and patent-pending silicon carbide (“SiC”) CTI as the energy source for Aurora’s patent-pending pyrolysis process, while improving cost efficiencies at large scale. Initial testing and design work has begun, while Acceleware and Aurora seek funding for this integration work. Acceleware intends to leverage its past success in securing non-dilutive funding and is exploring other avenues to finance the development of CTI technologies.

Acceleware’s CTI is a field-proven, proprietary industrial heating technology platform that could enable the cost-effective decarbonization of heavy emitting industrial heating processes via highly efficient delivery of radio frequency (RF) energy. The patent pending CTI heating ‘engine’ uses leading edge SiC technology that results in over 98 percent conversion efficiency from electricity to RF energy. CTI is reliable, can be adapted to multiple industrial heating applications, and is highly scalable.

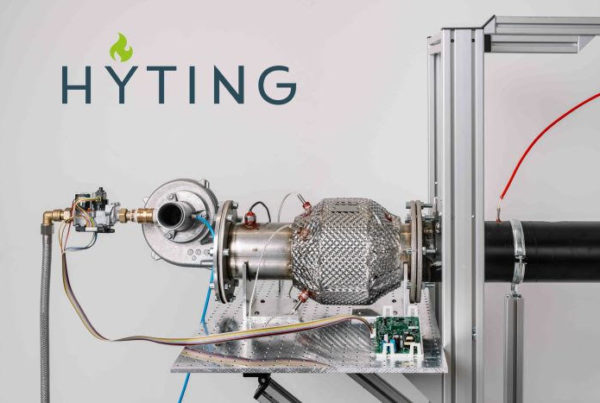

Aurora is developing a technology to generate low-cost, clean hydrogen directly at the point of use, eliminating the need for costly hydrogen transportation. Aurora’s technology uses efficient microwave or radio-frequency energy to turn natural gas into hydrogen and solid carbon, without using water nor generating any CO2 emissions.

Geoff Clark, CEO of Acceleware said, “we are very excited to be working with the Aurora team. This collaboration is a great opportunity to advance Acceleware’s vision of decarbonization at a global scale. Together, we see terrific potential for the CTI to improve the efficiency of the Aurora reactor while also establishing a fast-track to scale up industrial hydrogen production.”

“Aurora is very pleased to be working with Acceleware on developing what we believe could become the most efficient, scalable, and flexible hydrogen production process in the world,” said Andrew Gillis, CEO of Aurora Hydrogen. “We see great potential for the CTI to help us achieve these goals even sooner than anticipated and look forward to next steps.”

In addition to the Aurora collaboration, other potential CTI clean heat applications that Acceleware is exploring include applications such as commercial building heat, industrial process heat, and bulk solids and crop drying, among others.

ABOUT ACCELEWARE

Acceleware (www.acceleware.com) is an innovator of clean-tech decarbonization technologies comprised of two business units: Radio Frequency (RF) Heating Technology and Seismic Imaging Software.

Acceleware is piloting RF XL, its patented low-cost, low-carbon production technology for heavy oil and oil sands that is materially different from any heavy oil recovery technique used today. Acceleware’s vision is that electrification of heavy oil and oil sands production can be made possible through RF XL, supporting a transition to much cleaner energy production that can quickly bend the emissions curve downward. Further, Acceleware’s RF XL technology could eliminate greenhouse gas (GHG) emissions associated with heavy oil and oil sands production. RF XL uses no water, requires no solvent, has a small physical footprint, can be redeployed from site to site, and can be applied to a multitude of reservoir types.

Acceleware has partnered with Saa Dene Group (co-founded by Jim Boucher) to create Acceleware | Kisâstwêw to raise the profile, adoption, and value of Acceleware technologies. The shared vision of the partnership is to improve the environmental and economic performance of the energy sector by supporting ideals that are important to Indigenous peoples, including respect for land, water, and clean air.

The Company’s seismic imaging software solutions are state-of-the-art for high fidelity imaging, providing the most accurate and advanced imaging available for oil exploration in complex geologies. Acceleware is a public company listed on Canada’s TSX Venture Exchange under the trading symbol “AXE”.

ABOUT AURORA

Aurora Hydrogen is developing a clean hydrogen production technology that utilizes efficient microwave or radio-frequency energy without generating any CO2 emissions or consuming water. The technology is highly scalable, units can be installed anywhere and can scale from small fueling stations to the largest industrial applications. Hydrogen production using Aurora’s technology has the potential to reduce global CO2 emissions by over 900 million tonnes per year. The company was founded in 2021 and is based in Edmonton, Canada.

For more information, please visit: www.aurorahydrogen.com.

Read the most up to date Fuel Cell and Hydrogen Industry news at FuelCellsWorks