Australian Company Start-up switcH2 is planning to extract hydrogen from the beer brewing wastewater.

The company is comprised of three former chemical engineering students from the University of New South Wales.

Khushal Polepalle, Constantine Tsounis, Bijil Subhash have been working on an innovative idea to convert wastewater into Hydrogen. The trio called switcH2 has identified several opportunities to commercialize their idea through a start-up venture.

“SwitcH2 is currently in Startmate’s start-up accelerator, which has received backing from Mike Cannon-Brooke’s Grok Ventures and Blackbird Ventures. The team was selected out of a pool of 300+ start-ups across Australia and New Zealand.

The start-up is targeting breweries as they present the low hanging fruit for on-site hydrogen production and utilization, due to their high volume of wastewater production and their current energy demands.”

In a recent interview with Brew News Bijil Subhash said,

“We were training to solve problems while enjoying a few cold ones” explained Subhash.

“We had the idea in mind for quite some time, especially during the late years of undergrad, as it combined our passion for beer and renewable energy.

“It was in our heads, but we didn’t pursue it as a business until late 2019.”

While the process on the surface seems relatively straightforward, there will be a number of considerations for brewers, including electricity costs, integration with existing brewing equipment as well as renewable and other energy systems, in addition to the question of what to do with the hydrogen output.

“Currently the plan we’re fiddling around with is retrofitting [the system] to existing processes, unless you’re starting a new brewery and can implement it from the get-go,“ said Subhash.

“It’s an easily-implemented turnkey solution, you basically just need to plug it into a wastewater outlet on one side and the hydrogen is produced on the other side.”

The team focused on an industry which has sustainability in mind but can also be resource-intensive, and produces a waste product which could be put to good use.

“Conventionally electrolysis has had a bad reputation, mainly due to its high energy consumption, and the fact that it uses pure water,” explained Subhash.

“In our case, we’re using wastewater which would normally be a cost to the brewery as they would have to pay to get it processed or removed.

“And by oxidising the organics in the wastewater, we are essentially producing hydrogen at a reduced energy demand than a conventional electrolysis would.

‘Ultimately, by using our solution, breweries can convert a cost-center into a profit centre.”

Energy use

Energy usage is always a major issue in a brewery, so adding another power-hungry system to the mix could be a barrier to entry for brewers, which Subhash acknowledged.

“A lot of breweries we’re looking at and speaking to are already powered by renewables in some sense, and they have very ambitious near-term sustainability goals.

“By operating our device during renewable hours, breweries are able to increase their uptake of renewables in the form of hydrogen, analogous to how a battery would function,” he explained.

SwitcH2 is working to mediate concerns about power. It has partnered with renewable energy companies to help develop a solution if breweries do not already have renewable energy systems such as solar powers in place.

The system is also a scalable one, so breweries of any size can implement it.

“Electrolysis technology in general does not change engineering efficiency with scale, so you can scale it up to whatever size you need,” he said.

Costs

“The cost of renewable electricity as well as the cost of electrolysers are estimated to decrease with time, which works in our favor in the long-term,” said Subhash.

In the event that renewable energy is used to power the electrolyser and the hydrogen is reused in the brewery, it could have good returns.

“Our current estimates are around 4 to 6 years of payback, but that depends on the size of the brewery,” he said.

“Renewable technologies beyond solar panels will be a key component for breweries that are looking to tackle ambitious sustainability goals, an angle that we are striving to achieve.”

Why Hydrogen?

Hydrogen has been recognized by world-leading research, government, and industrial organizations as the fuel of the 21st century. Hydrogen can be produced cleanly using renewably energy inputs, and once created, can be used as an energy source, when the sun doesn’t shine. When hydrogen is combusted, it produces energy much in the same way as petrol or natural gas does, emitting only water as a byproduct, and can be used for heating and industrial transportation. Hydrogen can also be reconverted back into electricity to power offices, auxiliary plant, equipment and cars.

Simply put, by producing hydrogen from solar energy (think solar panels), we are storing that solar energy in liquid to use whenever we need it. In other words, we are storing sunlight in a bottle.

switcH2 was founded in 2019 as a spin-off from the Particles and Catalysis Research Group at UNSW by three chemical engineers with diverse backgrounds spanning fundamental research, scale-up engineering, financial services, and strategy consulting. Together, the team dared to tackle some of the biggest issues faced by humankind in the 21st century; climate change, energy, and industrial waste. By combining fundamental switcH2 technology with a sustainable business model and industry incentives, we hope to transform the brewery industry into a sustainable and clean energy powerhouse, by utilizing beer waste, and converting it into clean-burning hydrogen fuel, one beer at a time.

How it Works

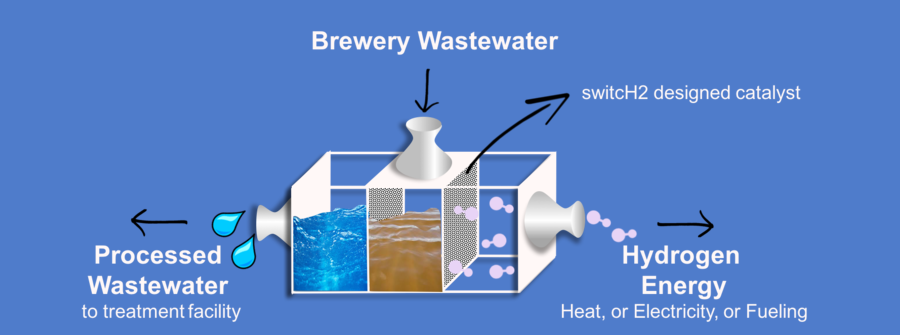

Swithc2 electrolyzer technology uses organic-rich brewery wastewater and renewable energy as the feed input to produce hydrogen. Compared to conventional electrolysis that uses pure-water to produce hydrogen, we are able to replicate the same chemical reaction using a resource that is purely a cost-centre to most breweries, thus creating value from a low-value waste stream. The electrolyzer works by passing an electric current through a catalyst, which then splits the water to form hydrogen on one side, and break down organics on the other.

Learn more at https://www.switch2engineering.com/

Read the most up to date Fuel Cell and Hydrogen Industry news at FuelCellsWorks