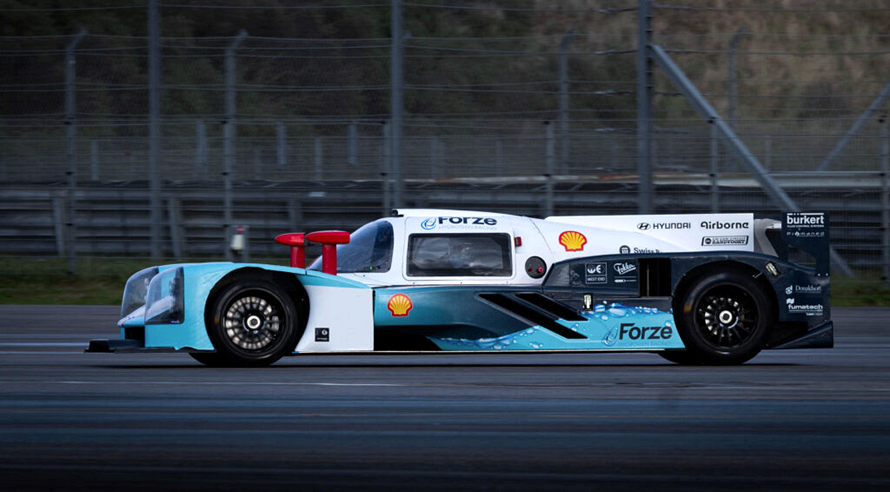

Last Monday, the new Forze IX of the Forze Hydrogen Racing team drove its first metres on the so-called superbattery at the Circuit of Zandvoort. With this milestone achieved, the next step is to integrate the hydrogen system into the car. The hydrogen racing car has a top speed of 300 kilometres per hour and will compete against the best production cars in the GT class of the Supercar Challenge. With the support of Airborne, the Delft students aim to demonstrate that hydrogen is not only sustainable, but also highly competitive on the track.

Racing with a clean exhaust

Forze and Airborne want to show the potential of hydrogen as part of the sustainable future of the automotive industry. In the car, hydrogen from the tanks reacts with oxygen from the outside air in a fuel cell, resulting in water and electricity. The team uses the electricity to power the wheels, where the only emission is water vapour, resulting in a clean exhaust.

After starting with hydrogen-powered go-karts in 2008, Forze built the first full-size hydrogen racing car in 2013. Afterwards, the team evolved to building endurance racing cars and was the first to compete in an official race against conventional petrol racing cars. The previous model even finished on the podium during a race on the Circuit of Assen in 2019.

Huge challenge

The students are taking a giant leap forward in hydrogen technology with their new car. The car’s intended use is racing, so the team focuses on performance. The race car will have two fuel cells, four electric motors and an 8.4kg hydrogen capacity, which the team aims to use to drive faster and longer than ever before. The Forze IX will have a peak power of more than 800 hp. This power is partly generated by the two hydrogen fuel cells, but also by an additional supercapacitor energy storage system, which can give a huge power boost to the car.

That energy storage system is precisely what allowed the car to make its first metres. While the hydrogen system was developed simultaneously outside the car, the team focused on setting up a reliable powertrain. Now that this part of the car is ready, the focus can shift to optimising and integrating the hydrogen system.

Valuable partnership

With the support of Airborne, Forze is ready to take the next step by racing against the best production cars. Airborne is of great value to the team both by assisting with knowledge and consumables for the production of carbon parts.

About Airborne

At Airborne we know that innovation in manufacturing through automation, digitalisation and advanced analytics is the catalyst for the significant increase in productivity that companies need to stay competitive. We understand the complexity and cost involved in producing composite products for demanding applications in highly regulated industries. Our legacy in advanced composites manufacturing makes us experts in developing and delivering automated solutions that enable our customers to achieve high production rates and radically low conversion costs. www.airborne.com

SOURCE: Airbone

Read the most up to date Fuel Cell and Hydrogen Industry news at FuelCellsWorks