- A German start-up company has developed a unique composite membrane. Combined with non-precious catalysts, it provides a cost-effective platform for alkaline water electrolysis, speeding up and improving the efficiency of hydrogen production.

Hydrogen produced via carbon-free electricity can be used in a broad range of applications across virtually all energy sectors — transportation, industrial, residential, and portable. This sustainable energy carrier channels significant amounts of power into sectors that are difficult to decarbonise through electrification. The EU-funded project MEMBRASENZ is an important milestone on the path to empowering this renewable energy transition.

Boosting electrolysis efficiency

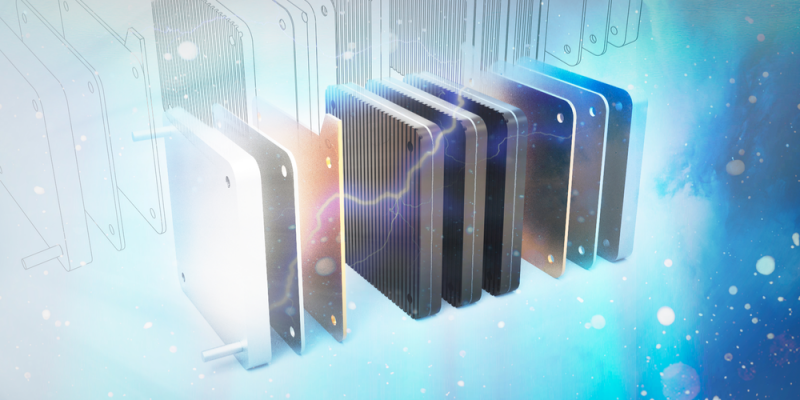

Electrolysis is a promising option for producing hydrogen from renewable resources. Amongst different types of electrolysers, alkaline ones operate via the transport of hydroxide ions through the electrolyte from the cathode to the anode, with hydrogen being generated on the cathode side.

High-quality membranes are highly valued – they can separate pure hydrogen from a gas mixture. “Electrolysers can contain membrane material of extremely large total surface area of around 1 000 m2. The key to MEMBRASENZ success is the use of a composite material optimally tailored to fulfil the stringent contradicting requirements for membranes in alkaline electrolysis,” explains Jelena Stojadinovic, CEO and founder of MEMBRASENZ GmbH, the project coordinator. Furthermore, this advanced new membrane for sustainable hydrogen generation meets purity requirements and can be integrated into existing industry, energy, and mobility infrastructures.

Design of the MEMBRASENZ membrane overcomes the shortcomings of asbestos, which has now been banned, and the standard replacement product Zirfon®. Although the latter diminishes the negative impact on health and the environment, it has some show-stopping downsides including insufficient mechanical and thermal stability, higher level of oxygen permeability at temperatures above 100 degrees Celsius and lower ion conductivity, all affecting the cost-effectiveness of hydrogen production. “Our advanced new membrane increases the efficiency of the electrolysis process due to improved gas tightness, ionic conductivity and thermal resistance of the newly developed composite material,” notes Stojadinovic.

“MEMBRASENZ hydrogen membrane is the only one on the market that can withstand temperatures above 100 degrees Celsius,” adds Stojadinovic. After 600 hours of in situ testing of the membrane at 120 degrees Celsius, the material performance did not degrade and the electrolysis process retained stable voltage. For comparison, the competitive state-of-the-art membrane degrades at 100 degrees Celsius. Increasing the cell temperature considerably lowers the voltage required for electrolysis to take place and results in maximising the system efficiency.

Vital link in the energy transition

Demand for hydrogen production is projected to witness exponential increase over the coming years. According to the MEMBRASENZ market study, annual production of hydrogen was pegged at over 50 million tonnes, which translates to EUR 450 billion, and is set to grow sixfold by 2025.

Water electrolysis is a central technology of the energy revolution as it is the only low-emission hydrogen production process. “At wind and solar energy sites, excess electricity not supplied directly to the power grid can be used to perform electrolysis, with the hydrogen stored for later reuse. Grid-tied and off-grid power-to-X systems help balance volatile renewable energy generation,” notes Stojadinovic. Hydrogen fuel cells already power Toyota, Honda, Hyundai and Mercedes vehicles as well as bus fleets and Alstom high-speed trains in Germany.

Installation of MEMBRASENZ membranes in alkaline water electrolysers worldwide will increase uptake of electrolysis for hydrogen production, helping supply green hydrogen to many different sectors. MEMBRASENZ membrane promises to significantly increase process efficiency, reduce electricity consumption and cut down billions in operating costs.

Read the most up to date Fuel Cell and Hydrogen Industry news at FuelCellsWorks