Fuel cells, hydrogen, and methanol engines are paving the way towards sustainable power generation and off-highway mobility.

The question of whether drive technology and power generation need to be green is no longer an issue, because unless this happens the goals of the Paris Climate Accord – limiting global warming to well below two degrees Celsius (ideally 1.5 °C) – will be impossible to achieve. The only question now being discussed across the world is ‘how?’. There is no clear-cut answer. What part will combustion engines play? What potential do fuel cells have? Which fuels are key?

However, in just a few years’ time the choices are set to widen, and when that happens operators will face a choice: batteries or fuel cells? Or what about an internal combustion engine that’s no longer powered by conventional fossil diesel, but by renewable e-fuels such as e-hydrogen, e-methanol, or e-diesel?

‘The key to transforming off-highway mobility lies in the fuels,’ says Dr. Daniel Chatterjee, Director of Technology Strategy & Regulatory Affairs at Rolls-Royce’s Power Systems division. Thanks to modern Power-to-X processes that use electrolysis to turn green electricity into hydrogen, which is in turn processed into e-methane, e-methanol or e-diesel, an entirely new range of drive power technologies will soon emerge.

Batteries only in niche applications

The foundation for all green fuels is electricity created from renewable energy sources.

The most obvious solution would be to store it directly in batteries and use it to power electric motors – as will probably soon be standard practice in passenger cars. But ships traveling long distances or dump trucks moving large loads would call for batteries of gargantuan proportions. Running a 2,000 kW diesel engine for 8 hours would need batteries weighing around 100 metric tons.

When wind or solar power is stored in a battery, 70 to 90% of it is usable for propulsion. If, on the other hand, the electricity is converted first to an e-fuel, the amount of original energy available for use is a mere 40%, the rest having been consumed by production and transportation. In other words, up to five times more energy input is needed to produce the final propulsion power. But an important parameter is missing in this calculation: energy density. Running, an engine at an output of 2,000 kW for eight hours would take the input of over 100 metric tons of batteries, or alternatively around 2 metric tons of diesel. The energy density of diesel is unbeatable.

‘Electric powertrains powered by batteries will only become established in niche areas of the off-highway segment – in other words in the largest of off-road vehicles – of that we’re certain,’ said Dr. Peter Riegger, Vice President of the Power Lab at Rolls-Royce Power Systems.

Fuel cells, on the other hand, are a much more realistic proposition – for propulsion and power generation alike. Strictly speaking, fuel cell systems are also electric drives. The only difference is that the electric motor is driven not by batteries, but by a fuel cell. Inside the fuel cell, a controlled chemical reaction takes place between hydrogen and oxygen, producing electricity that powers the electric motor. Emissions are almost non-existent – just water vapor. Only a small amount of heat is given off, which is why what happens in the fuel cell stacks is also referred to as ‘cold combustion’.

Developing fuel cell systems ready for market‘In a few years’ time we’ll be supplying fuel cell solutions,’ says Riegger. They promise exactly what we all need for a green future: zero-carbon mobility and zero-carbon power generation. Another major advantage of fuel cells over internal combustion engines is that they are scalable and extremely versatile in applications, meaning that if more power is needed, more fuel cell modules can be added on.

This also happens in operation: To date, propulsion power – for example in ships – is produced mainly by diesel engines whose power rating has to correspond to the vessel’s maximum power requirement. Fuel cells, however – especially when combined with batteries – open new possibilities, allowing the vessel to constantly adapt the amount of power being generated to match its current power requirement, saving fuel in the process. When a lot of power is required, all fuel cells are used, but when the ship is at low speeds, some fuel cells can simply be switched off.

Fuel cells for stationary power supplies

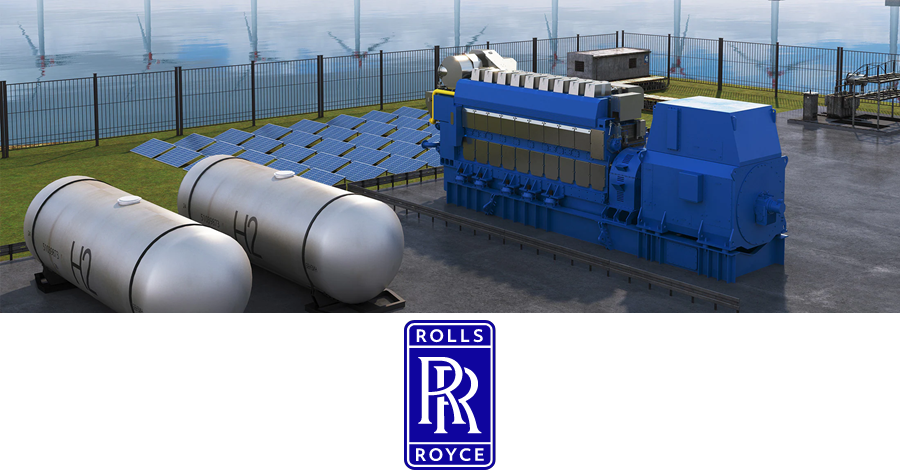

But its not only propulsion where fuel cells are a real alternative to combustion engines. Electricity generator sets are another application set to be revolutionized. For example, they can be used to supply climate-friendly emergency power to data centers and hospitals, replacing diesel generators within microgrids, or to provide permanent green power wherever no grid connection is available.

Tug propulsion solution with fuel cells and batteries

Propulsion and drive systems using fuel cells and batteries are extremely versatile: The amount of power being generated can be matched to the vessel’s power requirement at any given time, thereby enabling fuel savings. When the vessel mode does not require maximum power or speed, only the number of fuel cells needed is actually switched on. When maximum power is called for, all fuel cells are switched on, and the energy stored in batteries is also used.

As early as autumn 2021, we will be putting a fuel-cell-powered standby power supply demonstrator into operation at our facility in Friedrichshafen.

‘We want to use this demonstrator to show how versatile fuel cells can be when used in stationary power supply systems – for standby power applications, teamed with batteries for uninterruptible power supplies and also for prime power supplies,’ says Riegger.

And a demonstrator isn’t the end of the story. When it comes to stationary power supplies using fuel cells, Rolls-Royce Power Systems is teaming up with Cellcentric, the fuel cell joint venture between Daimler and Volvo, to develop a range of total solutions. ‘We’re currently developing scalable, fully-integrated solutions with up to 2 MW of output, for example for data centers,’ says Riegger. Each individual fuel cell module will initially have an output of 100 kW. These will be linked and controlled using smart technology. The customer’s power requirements will then determine the number of individual modules and thus the size of the overall system.

On its way: the hydrogen-powered combustion engine

No doubt about it: the fuel cell is hugely promising as we move forward towards climate-neutral power delivery and power generation.

But it is not about to usher in the end of the combustion engine.

‘The internal combustion engine has not had its day. Using synthetic fuels such as hydrogen, produced from renewable energy sources, it is set to remain a key technology going forward,’ says Riegger with conviction. our engineers are currently developing a hydrogen engine.

They are currently testing the technology on the single-cylinder test stand as part of the MethQuest R&D project. If the tests continue to be promising, a full-configuration engine is to be tested on the test stand before the end of 2021. ‘So far, with the hydrogen engine, we’ve mainly been focusing on stationary power applications, but we also see potential in the industrial and rail sectors,’ says Riegger.

Under the MethQuest project, our engineers are looking at using an innovative large spark-ignition engine to run on hydrogen. Used in power generation, the aim is for this engine to achieve the power density of a natural gas engine with low emissions.

To be carbon-neutral, hydrogen must also be green as a source of energy, hydrogen has a great future ahead of it. But if power delivery and power generation technology is to be truly climate-neutral, it must be produced from renewables. The trouble is, this ‘green’ hydrogen remains difficult and expensive to obtain. However, the European Union’s Green Deal and international water strategies and programs could soon change that. Factories for mass production are currently being built all over the world and are having the effect of reducing costs.

But hydrogen is not set to be the only fuel with the potential to ‘green up’ the world’s power delivery and power generation technology. It can be processed into things like methanol – a fuel that is of particular interest to the shipping industry. It is easier to handle than hydrogen, and the existing infrastructure can be used to transport it. Our development teams have their sights set on methanol-powered combustion engines too. And as if that weren’t enough: using a reformer, methanol can potentially also be converted back into hydrogen which could then be used directly in a fuel cell to produce electricity.

The green energy revolution calls for everyone to pull together we’re in the middle of an exciting transformation right now. Climate-neutral mobility and power generation are possible and will come. From now on, it’s all about teamwork. It’s only by working together with our customers, partners and the politicians who create the framework that we can make the green energy revolution a reality,’ sums up Peter Riegger.

Read the most up to date Fuel Cell and Hydrogen Industry news at FuelCellsWorks