- Hyundai Engineering, SK Eco Plant, and USNC signed a three-party MOU for hydrogen production.

- Conducted joint R&D for the commercialization of ‘Hydrogen Micro Hub’ over the next five years.

- Hydrogen by combining MMR applied with a 4th generation reactor and SOEC, a next-generation water electrolysis technology Production.

Hyundai Engineering (CEO Hong Hyun-seong) and SK Ecoplant (CEO Park Kyung-il) collaborated with USNC (CEO Francesco Beneri), a company specializing in MMR (Micro Modular Reactor), to produce hydrogen without carbon emissions. engage in R&D.

Hyundai Engineering, SK Eco Plant, and USNC announced on the 20th (Thursday) that they had signed a three-party MOU for the establishment of a ‘H2 Micro Hub’ at SK Eco Plant’s headquarters in Jongno-gu, Seoul.

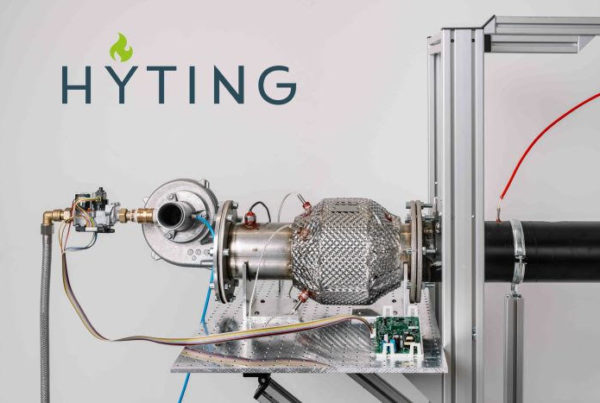

The ‘Hydrogen Micro Hub’ is a facility that produces hydrogen by applying the high-temperature water electrolysis process of the Solid Oxide Electrolysis Cell (SOEC) to electricity and high-temperature steam generated from MMR. It is a hydrogen production method without carbon emission that extracts hydrogen by decomposing water with electricity made using nuclear power.

According to the agreement, the three companies will jointly conduct R&D on an MMR-SOEC-linked integrated plant for the next five years. Through this, it plans to review the establishment of a price-competitive hydrogen production system and promote continuous R&D and demonstration for hydrogen production and supply business in the future.

In this project, Hyundai Engineering is in charge of MMR-related BOP (Balance of Plant) and EPC (Design, Procurement, and Construction) tasks, and USNC is responsible for MMR design, manufacturing, and supply. SK Ecoplant plans to configure a nuclear power plant-based water electrolysis hydrogen production system and supply hydrogen production facilities through Bloom Energy’s SOEC.

In this project, Hyundai Engineering and USNC cooperate to utilize MMR, which is applied with a 4th generation nuclear reactor based on High Temperature Gas-cooled Reactor (HTGR), which is undergoing a demonstration project in the Choke River region of Canada. Since it can generate relatively high-temperature steam compared to currently commercialized light-water reactor-based nuclear power plants, SOEC operating at high temperatures can maximize hydrogen production efficiency with less energy.

Meanwhile, SK Eco Plant, along with Bloom Energy and Bloom SK Fuel Cell, succeeded in the test production of hydrogen by water electrolysis through a 130kW SOEC facility in the Bloom SK Fuel Cell manufacturing plant located in Gumi, Gyeongbuk. Recognized for its differentiated technological capabilities for high-efficiency hydrogen production, it is also participating in a government-sponsored green hydrogen production demonstration project. A project to convert green hydrogen into ammonia or methanol with high storage capacity is also being promoted. It is evaluated that it has completed the renewable energy-based green hydrogen value chain, from the development of renewable energy businesses such as offshore wind power and solar power to the production of related equipment and materials, EPC, and green hydrogen production.

SKIn addition to this, based on this hydrogen micro-hub construction cooperation, Eco Plant plans to have a diversified ‘hydrogen production model without carbon emissions’, including so-called pink hydrogen produced by decomposing water with electricity generated through nuclear power generation.

Park Kyung-il, CEO of SK Ecoplant, said, “SOEC operates at high temperatures and can produce high-efficiency hydrogen with little energy, so it is a good partner to make the most of the advantages of MMR, which generates high temperatures.” In addition to the base green hydrogen value chain model, we will lead hydrogen production without carbon emissions, including economic hydrogen production using nuclear power.”

Hong Hyun-seong, CEO of Hyundai Engineering, said, “We have signed a business agreement between the three companies to economically produce and supply hydrogen by combining two eco-friendly technologies, MMR and SOEC.” We are continuing our efforts in various fields, such as recycling plastic resources, renewable energy such as offshore wind power and solar power, and supplying electric vehicle charging infrastructure.

” It is an efficient and economical hydrogen production plant that can produce hydrogen,” he said. “SK Eco Plant, Hyundai Engineering, and USNC will contribute to building an efficient hydrogen economy based on the MMR-SOEC integrated plant.”

Read the most up to date Fuel Cell and Hydrogen Industry news at FuelCellsWorks