On the way to a climate-neutral future, e-mobility plays an important role in transport and logistics. The claim to further reduce CO2emissionsis a key driver of the increasing use of drive alternatives. The topic is not new for the intralogistics industry: more than 50 years of experience with electrically driven industrial trucks already exist.

Various battery technologies and their performance as well as the required charging infrastructure are known. Around 90 percent of Toyota Material Handling’s entire portfolio are electric forklifts, which are available with both classic lead-acid batteries and lithium-ion technology.

The good energy efficiency of lithium-ion technology enables the operator not only to save energy costs, but also to reduce CO2emissions. But what if the available power capacities are not sufficient for this technology or if there is not enough time and space for charging processes? Then fuel cell propulsion with hydrogen can be an answer.

Toyota’s pioneering role in fuel cells

In the automotive sector, Toyota is regarded as a pioneer and innovation leader in alternative drive systems in the field of electric, hybrid and fuel cell technology.

Stefanie Beck, Speaker, Toyota Motor Europe – Berlin Office

As early as 1997, Toyota embarked on the path to e-mobility with the Prius.

“The inventor and godfather of our hybrid technology (and also of fuel cell technology), Takeshi Uchiyamada, has been our Chairman since 2013. A proven R&D expert in this position underlines the great importance of drive diversification for our Group.”

Since 2014, Toyota has been producing the world’s first fuel cell car Toyota Mirai and will launch the second generation of the fuel cell sedan in Japan this year, with the market launch in the USA and Europe in 2021.

The fuel cell components for the Toyota Mirai will be manufactured in a technology plant in Japan, which will not open until 2020. In the first year, 30,000 fuel cell stacks and hydrogen tanks will be produced there, which will be used on the domestic market in particular for other commercial vehicles, such as buses.

In Germany, too, this technology has now more than arrived. Several 100 Toyota Mirai are on the road in Germany, and the refuelling infrastructure for hydrogen is being continuously expanded. The expansion will be accelerated by state funding.

The German Hydrogen Strategy

The fuel cell was recently named by the Federal Government as a future technology of the utmost importance as part of the announcement of the national hydrogen strategy. It converts hydrogen into water with the help of atmospheric oxygen. During this chemical reaction, electrical energy is released that drives electric motors.

As part of the national hydrogen strategy, various federal ministries are currently driving the development forward, because the flexible energy carrier is indispensable for the energy transition in Germany.

The aim is to establish an internationally competitive hydrogen economy. That is why the federal government is providing 9 billion euros in funding. More information on the specific content of the strategy can be found here.

The spirit of optimism is also reaching the transport and logistics industry. However, while the commercial vehicle industry for road freight transport in Europe is still largely in the development phase, fuel cell technology for industrial trucks is already in use.

How is a fuel cell constructed?

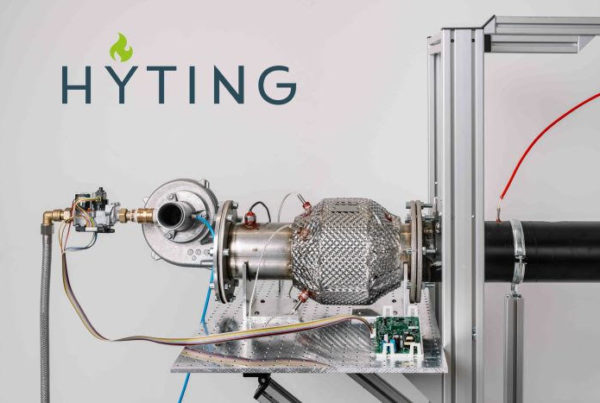

At the heart of the hydrogen drive for forklifts and warehouse equipment is the fuel cell system,consisting of the fuel cell stack, the hydrogen tank (350 bar), an energy storage in the form of a smaller lithium-ion battery and the fan.

The battery is used to temporarily store energy that is not needed or obtained by recuperation in order to have it quickly available again for load peaks. Designed into a cast frame the size of a classic lead-acid battery, the system can be installed relatively easily and with minor modifications in a conventional electric forklift.

Successfully implemented fuel cell forklift fleets in the USA and Europe

Currently, around 90 percent of Toyota’s electric industrial truck fleet is already available with fuel cell drive and certified according to European guidelines. More devices will follow. In the USA, Toyota Material Handling and its subsidiaries have already implemented projects with up to 500 units, including narrow-aisle units, reach trucks and tractors.

Users include companies in the food industry, the automotive industry, (mail order) trade and logistics as well as airports and ports. But also in its own production facilities in Japan and Italy as well as at customers in France, Norway and Finland, the world market leader for industrial trucks operates part of its fleet with hydrogen and thus already has many years of practical experience in operation.

The lifting tower plant in Ferrara, Italy, serves as a pilot plant for Toyota Material Handling Europe. Here, important insights for customer projects are gained – both from practical tests with the company’s own hydrogen forklift fleet and from cooperation with partners in the planning and needs-based development of the hydrogen infrastructure.

Using federal funding programmes and regional initiatives

Viewed worldwide, the US market is currently the leader with around 32,500 fuel cell industrial trucks in use. Reasons for this include tax incentives and an existing hydrogen industry. Japan is even aiming to produce 10,000 hydrogen forklifts by 2030, while only around 600 units are currently in use in Europe – even though the technology has been tried and tested and is ready for use.

This is set to change with the Federal Government’s national hydrogen strategy and special funding programmes for operators of forklift fleets.

In order to promote the expansion of hydrogen-powered fleets and refuelling infrastructure, the Federal Ministry of Transport and Digital Infrastructure (BMWi) is funding companies with a total sum of 5 million euros as part of the “National Innovation Programme Hydrogen and Fuel Cell Technology”. More information on how to apply can be found here.

Wolfgang Axthammer, Managing Director of NOW GmbH and Program Manager Special Markets

Investments in forklift fleets as well as the entire hydrogen infrastructure required for this are supported with a subsidy rate of 40 percent of the additional investment costs.

“Funding can be an important aid for projects. Companies can still report their interest until 20.11.20 for the year 2021.”

With this financial support, around 500 additional industrial trucks with the innovative technology are to be put into operation in Germany by 2022.

In its current study “Impact of fuel cell technology on the machinery and component supplier industry”, the German Engineering Federation (VDMA) sees the market share of hydrogen-powered forklifts at 10 to 20 percent by 2030, depending on the performance class.

Overall, manufacturers are already seeing greater interest and increasing demand for hydrogen solutions as a drive for industrial trucks, especially in new logistics center construction projects.

Advantages of fuel cell technology for industrial trucks:

- Emission-free operation, only distilled water as a “waste product”

- Time savings due to the elimination of battery changes or downtimes during the charging process

- High device availability, as refueling takes only 2-3 minutes

- No land consumption, no investment in cargo spaces or ventilation systems

- Very flexible even during order peaks, additional refuelling is possible at any time

- No handling of toxic chemicals such as battery acid or lead

- CO2-neutral when using “green” hydrogen

- No drop in performance during use

- Durability and low maintenance

- Can be used in the temperature range from – 30°C to 40°C

Why now is the right time to run forklift fleets on hydrogen

The current upswing of fuel cell applications in other branches of industry, especially in the commercial vehicle segment, will provide an impetus for the expansion of the hydrogen infrastructure in Germany and Europe and further reduce the price of hydrogen and thus the operating costs for fuel cell forklifts.

To this end, energy suppliers are currently developing various solutions to transport and store hydrogen or to produce it on site from renewable energy. Hydrogen distribution within the building or over a site is possible both underground and in thin pipes over the roof, so thatfilling stations can be positioned where the industrial trucks are in use.

The infrastructure outside the building is limited to a small area for storing the compressor station, the intermediate storage tank and the distribution station.

The road to hydrogen with Toyota Material Handling

While electricity costs in Germany are rising continuously, the price of hydrogen is also falling with the increasing production volumes due to publicly funded green hydrogen projects.

Hydrogen-powered forklifts not only score points with their zero emissions, but also offer maximum availability around the clock thanks to their fast refuelling.

In addition, the larger the fuel cell fleet and the more operating hours per device, the better distributed the investments in the hydrogen infrastructure and the costs for its regular maintenance. Thus, a large fleet with a high capacity utilization contributes to a faster amortization of costs.

Fuel cell technology is already making a decisive contribution to reducing theCO2footprint of companies. As a project planning and implementation partner, Toyota Material Handling not only offers the broadest portfolio of industrial trucks, but also has numerous project experience and a network of competent planners, experts and suppliers for the hydrogen infrastructure.

Reliable and experienced partners are important, such as spending actively involved in the network for greenintralogistics ( Clean Intralogistics Net) with fuel cells, whose spokesman is Toyota.

Take advantage of the opportunities and potential that hydrogen technology already offers for intralogistics and combine climate protection and sustainability with investment security in an innovative technology.

Source: Toyota Germany / Kai Hesse

Read the most up to date Fuel Cell and Hydrogen Industry news at FuelCellsWorks