Frankfurt am Main – Science and industry attach considerable importance to hydrogen for the generation and use of clean energy.

In turn, gas analysis plays a very central role in H2 production and ongoing process control. A highly innovative sensor technology from Archigas, recently presented for the first time and developed to market maturity, is tantamount to a quantum leap here and is causing quite a stir among experts. Renowned scientists from the RheinMain University of Applied Sciences (HSRM), which was involved in the development, explain why the microsensors are becoming a game changer:

“The importance of being able to make hydrogen usable on a large scale is increasingly being recognised. Among other things, sensors that are more stable and more economical, and which can be reliably produced in large quantities, are urgently required“, concludes Prof Dr Birgit Scheppat, professor of hydrogen and fuel cell technology.

“If you look at the entire hydrogen chain, spanning production, distribution, storage and combustion, it becomes clear that sensors are needed at all points in this chain. But the hydrogen sensors in use today are either extremely big or extremely expensive, and are subject to ageing. These disadvantages can be countered by using sensors based on so-called MEMS – microelectromechanical systems. The manufacture of MEMS sensors is already established. Every one of us permanently carries dozens of MEMS sensors about with us, in our mobile phones“, says Prof Dr Markus Bender, professor of micro and nanotechnologies.

“Due to H2 technology’s wide range of applications, the sensor systems required must have a dynamic range that is as great as possible. Hydrogen sensors used with gas mixtures must be able to detect not only relatively high H2 concentrations, but also extremely low concentrations. The newly developed sensor solutions for hydrogen detection are based on the thermal conductivity measurement principle (TCD sensors). The H2‘s concentration in gas mixtures can thus be determined extremely precisely“, judges Prof Dr Friedemann Völklein, director of the Institute for Microtechnologies, 2004–2019.

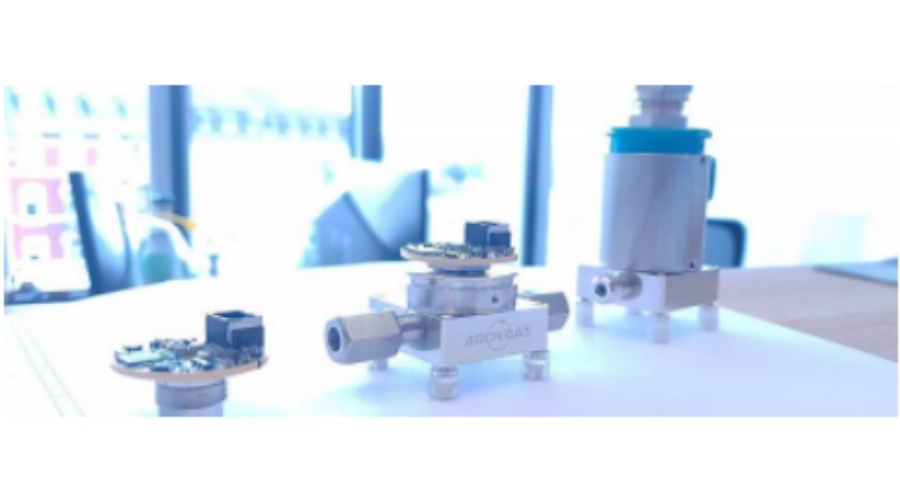

Thanks to their unique operating mode and design features, the new analyzers from H2 pioneer Archigas fulfill all of the above aspects – and can thus make a significant contribution to the effective development of hydrogen in the present and future.

Facts at a glance

- The sensors are characterised by their extraordinarily high stability and sensitivity. As so called TCD sensors they are based on the thermal conductivity measurement principle. This enables the H2 concentration in gas mixtures to be determined extremely precisely

- The sensors are characterised by the fact that MEMS technology (microelectromechanical systems) is intelligently used in their production – in other words, proven semiconductor technology based on silicone wafers. In turn, this permits economical mass production of sensors that are absolutely identical, without the need for complex calibration

- The sensors can be installed in numerous places within the scope of measurement technology and safety measurement: On this basis, gas measurement equipment is designed and produced for among other applications H2 production using electrolysis, input quality control and the testing of gas purity, and the control and monitoring of gas mixtures

- The devices’ easy handling enables quick, trouble-free implementation of the TCD OEM modules into customer equipment such as gas chromatographs, synthesis gas plants and many others

- The business also has concepts for mass flow measurement that is independent of the gas type, and therefore unique worldwide, along with systems for industrial vacuum and temperature measurement

- Close research work with the RheinMain University of Applied Sciences and funding from the state of Hesse both represent an important basis for the products’ development • With immediate effect, Archigas GmbH, with its administrative headquarters in Frankfurt and new laboratory and production site in nearby Rüsselsheim, offers its innovative H2 measurement technology in different variants

Read the most up to date Fuel Cell and Hydrogen Industry news at FuelCellsWorks

Archigas is highly specialised in microsensor technology (MEMS) and gas analysis. Since its foundation in 2020, the company has developed sensor solutions, particularly in the fields of thermal conductivity, pressure measurement and flow measurement. Archigas’s stated aim is to offer customers cost-effective plug and play solutions that reliably fulfil highly complex analysis tasks. Since 2022 the company has also been funded by the state of Hesse as part of its LOEWE programme (‘State Offensive for the Development of Scientific and Economic Excellence’). This is to support work on the development of measuring devices suitable for the exploration of natural hydrogen and helium deposits. Despite international bids from the USA and elsewhere, Archigas GmbH decided to establish its headquarters in the Rhein-Main region, in order to help bolster the state of Hesse, and therefore Germany as a whole, as a location for business.