- ultrasonic dispersion liquid permeation method using a homogeneous catalyst nano-coating technology

- an increase in the durability of the solid oxide fuel cells operate at a lower temperature expected

Korea Institute of Energy Researchers from Dr. Seung-Bok Lee and Dr. Rak-Hyeon Song in the Fuel Cell Laboratory at Korea Institute of Energy Research revealed that the SOFC performance was improved more than two times by using the ultrasonic dispersion wet penetration method.

SOFC operates at high temperatures and has the highest power conversion efficiency of over 60% among existing fuel cells. A catalyst solution is used to accelerate the chemical reaction between hydrogen and oxygen.

The most important factor that determines the overall performance of a SOFC system is a unit cell composed of an anode, an electrolyte, and an air electrode. The slow oxygen reduction reaction in the cathode is one of the causes of deteriorating the performance of the SOFC unit cell.

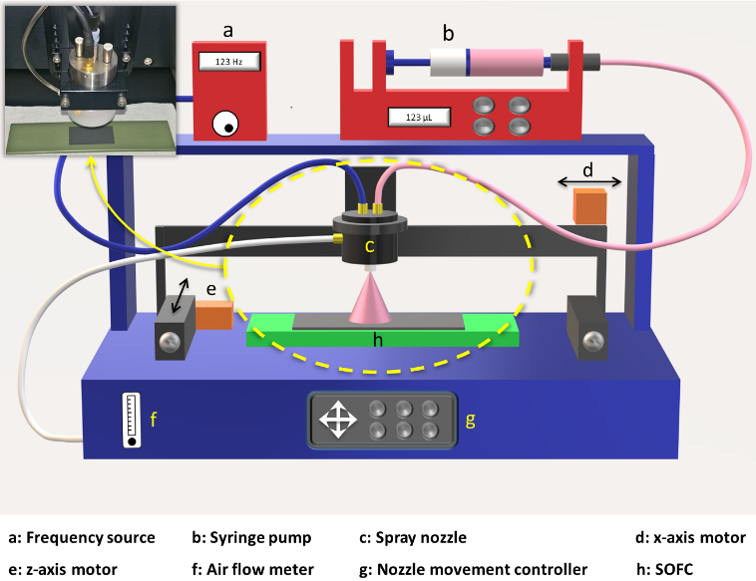

In the method using the existing micropipette, the droplets were larger than 1mm, which hindered the inflow of oxygen and reduced efficiency. To solve this problem, the researchers developed an ultrasonic dispersion wet penetration process. The ultrasonic dispersion wet permeation process is a technique that can apply a uniform catalyst layer quantitatively by using an ultrasonic device that can reduce the size of a droplet added by fine shaking by 0.01 mm.

To overcome this, the researchers developed an ultrasonic spraying infiltration technique. The ultrasonic dispersion wet permeation process is a process that can apply a quantitative, uniform catalyst layer by using an ultrasonic device that can reduce the size of liquid droplets added by microscopic shaking in units of micrometers ( about 10 -5 m).

Many studies have used a wet penetration method in which a catalyst is dissolved in a solution and added to the cathode layer in order to improve the oxygen reduction reaction in which oxygen introduced from the outside meets electrons. However, in the conventional wet penetration method using a micropipette, the size of the added liquid droplet was larger than 1mm, and the catalyst was condensed on the surface of the cathode and prevented the inflow of oxygen, thereby reducing the performance.

Through the ultrasonic wet penetration process, the SSC nanocatalyst layer grown on the LSCF layer, which is an existing SOFC cathode material, was confirmed, and as a result, the performance improvement effect was about 2.3 times more than that of the existing LSCF/GDC composite cathode. In addition, through transmission electron microscopy analysis, it was confirmed that the SSC nanocatalyst layer was grown in the same crystal structure on the LSCF cathode. The SSC nanocatalyst layer grown with the same crystal structure not only inhibits particle growth but also shows excellent long-term durability through excellent adhesion to LSCF.

Dr. Seung-Bok Lee said, “The ultrasonic dispersion wet penetration method is a technology suitable for commercialization that is easy for large-area SOFC cells and can form a new nano-catalyst functional layer in not only newly developed cells but also existing cells.” The nano-catalyst layer can be used as an important research result for improving SOFC performance in the future.”

On the other hand, this research National Research Foundation of Korea, climate change technology business, and Korea Institute of Energy Research, the main business, low-cost, high-performance core source materials developed for fuel cell construction, research results in international journals ” Journal of Materials, chemistry a (Journal of Materials chemistry a) , IF: 11.301 ”

Read the most up to date Fuel Cell and Hydrogen Industry news at FuelCellsWorks