HIGHLIGHTS

• Scalable second generation reactor design successfully tested at CSIRO Energy Centre in Newcastle, NSW

• Hydrogen gas production rates closely align with expected results from laboratory testing

• Substantial engineering and design improvements implemented since first generation prototype with design principles applicable to a pilot scale reactor

• First-of-its-kind pilot plant development works progressing

Sparc Technologies Limited (ASX: SPN) (Sparc, Sparc Technologies or the Company) is pleased to advise that Sparc Hydrogen, a joint venture between the University of Adelaide, Fortescue and Sparc Technologies, has successfully tested its second generation prototype photocatalytic water splitting (PWS) reactor at the CSIRO Energy Centre in Newcastle, New South Wales (see Figure 1). The completion of the second round of prototype testing was delivered on time and on budget by the Sparc Hydrogen team.

The design of the second generation prototype has built on learnings from the first round of testing completed in Q4 2023 (ASX Announcement 24 November 2023). Performance of the reactor over numerous trial runs and a range of concentrated solar and thermal operating conditions is significantly improved compared to the first generation prototype, with better temperature and pressure control, gas production and measurement. Hydrogen gas production was close to that which was estimated based on laboratory results using the same photocatalyst material, providing validation for laboratory testing under concentrated solar simulation going forward. Importantly, the second generation prototype has been designed to be easily scalable in order to slot into a linear Fresnel concentrated solar field for pilot scale testing, which is subject to Sparc Hydrogen board approval of Stage 2 of the joint venture.

Sparc Technologies Managing Director, Mr. Nick O’Loughlin, commented: “Sparc is very pleased with the progress in reactor design made over a short period of time by the hard-working Sparc Hydrogen team. The performance and design improvements that have been demonstrated through the second generation reactor validate the ongoing laboratory work along with the approach that Sparc Hydrogen has taken to on-sun scale-up as we head towards a pilot plant investment decision.

This prototype testing has persuasively demonstrated concentrated photocatalytic water splitting (PWS) in real-world conditions, which in turn reinforces the significant potential of PWS as an alternative to electrolysis for the production of low-cost green hydrogen. We continue to be encouraged by the market demand for alternative green hydrogen production technologies, given the challenges being faced by electrolysis projects globally.”

believes that the success of this round of prototyping, which has been supported through funding from Australia’s Economic Accelerator (AEA) grant program (ASX Announcement 19 October 2023) and the CSIRO Kick-Start Program, has fully satisfied the objectives set out at the beginning of the prototype testing (ASX Announcement 3 July 2023). Sparc is also pleased with the recent progress made by Sparc Hydrogen in developing relationships with leading photocatalyst suppliers with the aim of sharing materials for testing in Sparc Hydrogen’s PWS reactor. Sparc considers both reactor development and formalising relationships with photocatalyst developers to be important factors behind a decision to move forward with Stage 2 of the joint venture.

In parallel with the recent on-sun prototype testing, Sparc Hydrogen has continued to progress development workstreams for the pilot plant ahead of a decision to move to Stage 2 of the joint venture. A pre-FEED study completed by an external consultant during Q4 2023 demonstrated the ability for Sparc Hydrogen to build and fund a pilot plant incorporating modular, scalable linear Fresnel concentrated solar mirrors. If built, this would be a first-of-its-kind facility demonstrating the combination of photocatalytic water splitting with concentrated solar in an end-to-end green hydrogen production system. Recent work on the pilot plant has been focused on detailed reactor design incorporating the specific attributes of the chosen mirror field, site selection, budgeting and approvals. Sparc Hydrogen continues to apply for grant funding which would support the costs of R&D and pilot plant construction, albeit this is not a pre-requisite in order to fund the planned activities of the joint venture during Stage 2.

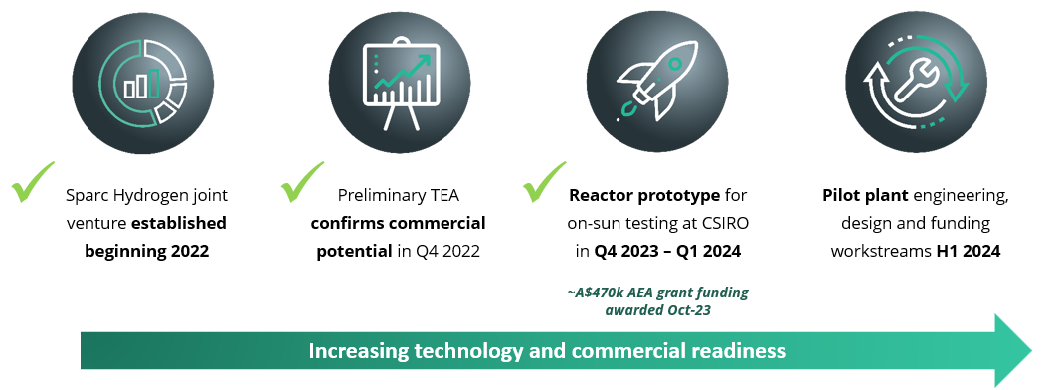

Stage 1 Development Milestones

About Sparc Hydrogen

Sparc Hydrogen is a joint venture (Sparc Technologies 52%, The University of Adelaide 28% and Fortescue 20%), developing next generation green hydrogen technology using a process known as photocatalytic water splitting (PWS). This process is an alternative to producing green hydrogen via electrolysis, using only sunlight, water and a photocatalyst. Sparc Hydrogen’s patent pending PWS reactor has the potential to improve the efficiency of PWS to obtain hydrogen from water using concentrated solar. Given lower infrastructure requirements and energy use, the ‘Sparc Green Hydrogen’ process has the potential to deliver a cost and flexibility advantage over electrolysis.

Sparc Green Hydrogen schematic demonstrating combination of concentrated solar and photocatalytic water splitting

About CSIRO Kick-Start

The CSIRO Kick-Start program is an initiative designed to support innovative Australian start-ups and small businesses in accessing CSIRO’s research expertise and capabilities to foster growth and development.

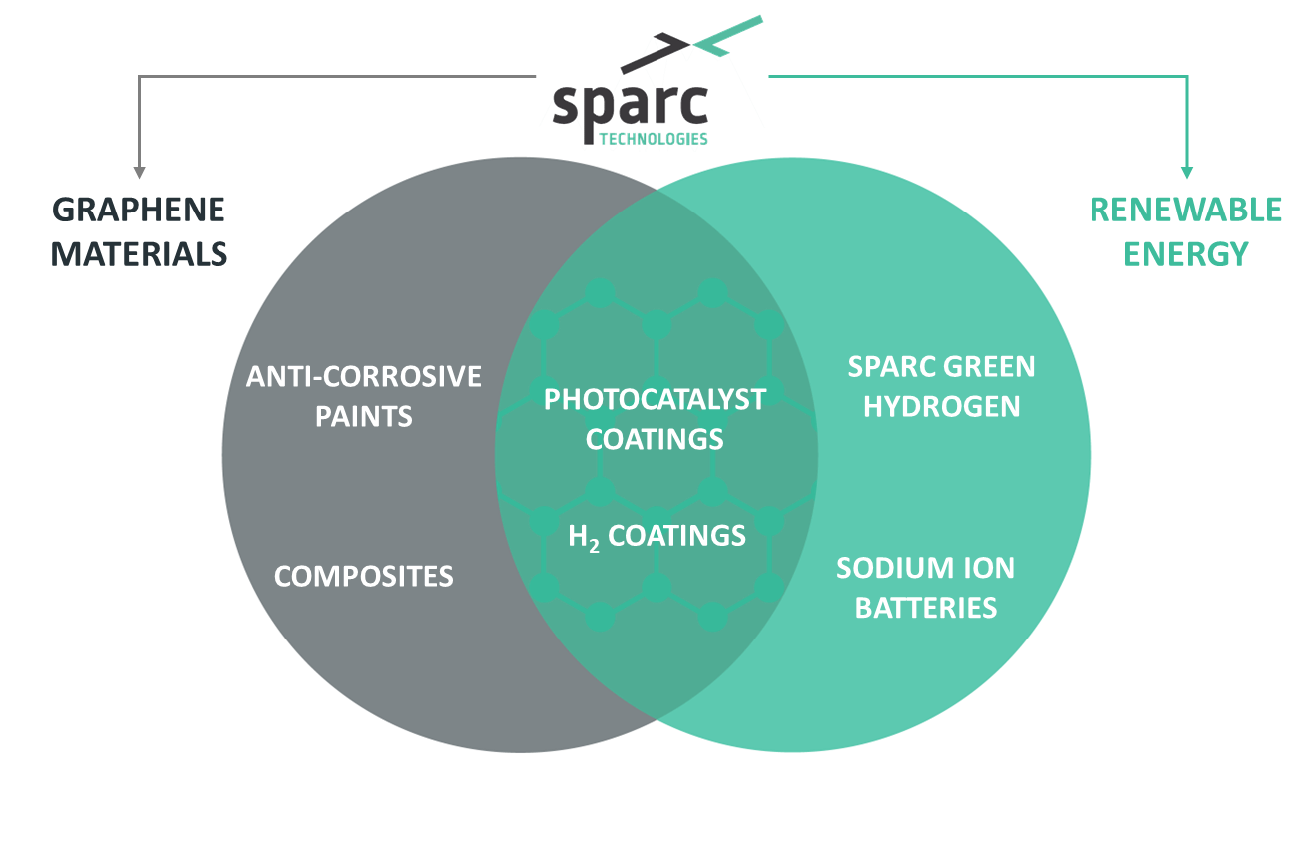

About Sparc Technologies

Sparc Technologies Limited (‘Sparc’, ASX: SPN) is an Australian company pioneering new technologies to disrupt and transform industry while seeking to deliver a more sustainable world. Sparc has established offices in Australia, Europe and North America and is focused on three core areas of technology development.

1. Sparc has spent over 4 years developing a graphene based additive product, ecosparc®, which has demonstrated up to 40% anti-corrosion improvement in commercially available epoxy coatings. Sparc recently commissioned a manufacturing facility to produce ecosparc® and is engaging with global coatings companies and asset owners to conduct field trials.

2. Sparc is a majority shareholder of Sparc Hydrogen which is a company pioneering the development of photocatalytic water splitting (‘PWS’) green hydrogen production technology. PWS is an alternative to producing green hydrogen via electrolysis, using only sunlight, water and a photocatalyst. Given lower infrastructure requirements and energy use, the process has the potential to deliver a cost and flexibility advantage over electrolysis.

3. Sparc is also developing sodium ion battery technology in partnership with Queensland University of Technology.

For more information about Sparc Technologies please visit: sparctechnologies.com.au

For more information about ecosparc® please visit: ecosparc.com.au

For more information about Sparc Hydrogen please visit: sparchydrogen.com

Read the most up to date Fuel Cell and Hydrogen Industry news at FuelCellsWorks