Jacksonville, FL O — Following nearly five years R&D, IP compilation, and 3rd party compliance consul, BrainDrip, LLC, and its wholly owned subsidiaries IQ4H2 Lab and New4H2 Hub, are initiating measured dissemination of their disruptive technologies for safely and efficiently meeting the world’s transition to hydrogen.

Following nearly five years R&D, IP compilation, and 3rd party compliance consul, BrainDrip, LLC and its wholly owned subsidiaries IQ4H2 Lab and New4H2 Hub are initiating measured dissemination of their disruptive technologies for safely and efficiently meeting the world’s transition to hydrogen. “As a pipeline innovations leader, early on we noted the immense international focus on hydrogen generation technologies and swiftly recognized the equally important need for the capability to safely and efficiently transmit, distribute and store that energy after production,” stated Kent Weisenberg, Managing Partner, and Team Principal, BrainDrip, LLC. “Noting that the current compliance doctrine for hydrogen pipelines was limited at best, and somewhat divergent of our normal conceptual development practices, our first step was to solicit 3rd party consul to assure that our initial design considerations, material interpretations and manufacturing methodologies would exceed any future regulatory compliance changes for hydrogen,” added Weisenberg. BrainDrip enlisted the professional services of the Houston based Energy Services and Solutions, a national leader in pipeline compliance, testing, inspection, and risk assessment. “Energy Services and Solutions continues to be a true and objective asset to our continuing developments and is possibly the only fossil energy compliance firm that has also initiated a unified focus on the future transition of the national gas pipeline infrastructure to hydrogen,” he added.

The SG Stage I and Stage II Liner systems are manufactured entirely onsite in the BrainDrip – IQ4H2 Lab’s patented and responsible hybrid Mobile Onsite Factory (MOF). “The MOF is a self-contained automated manufacturing facility that is truly mobile and drivable. Of importance, the MOF manufacturing and installation methodologies are not constrained to HDPE, or its derivatives as most all contemporary pipeline renewal systems are. Uniquely, our automated methodologies allow for the onsite utilization of any feedstock material such as thermoplastics, fluoropolymers, or even recycled water bottles and plant-based materials, lending it to be by far, the most versatile and environmentally responsible pipeline renewal and conversion system available globally,” stated Weisenberg.

“SG Technologies are a game changer for hydrogen and hydrogen blend distribution, repurposing of the U.S. pipeline infrastructure, as well as local hydrogen or RNG storage,” Mike Peters, Lead Hydrogen Consultant at EnServ, who served as an applied R&D Hydrogen Project Lead at the National Renewable Energy Laboratory (NREL) for the past 11 years. “Lining and vessel systems need to be designed with containment and reinforcement materials that can meet the required pressure ratings, permeation/diffusion, thermal and cyclic strain resistance imposed for the safe and effectual transmission and storage of hydrogen. The BrainDrip team appears to have addressed these current systemic obstructions with validated solutions through novel thinking, teamwork, and applied science,” he included.

The SG Liner was developed for the conversion of existing pipelines to the transmission, distribution and or the line pack storage of hydrogen. The SG Liner is suitable for pipelines with diameters from 4 inch to 36 inch and dependent on diameter, production rates of up to 20 feet per minute, installation lengths of over 30 miles from a single ingress and more importantly pressure ratings of approximately 500 bar. “Due to the molecular structure and weight of hydrogen we realized that high compression was key to the economics of hydrogen transmission and storage, so early on, the team’s practical foresight and directive was to design our own reinforcement materials as well as a unique method of its layered appointment,” stated Lin Li, Ph. D., Principal Mechanical & Structural Engineer, BrainDrip, LLC. “Through 3rd party validation, our novel Micro-Rope reinforcement filament has demonstrated dramatically increased breaking efficiency therein providing breaking loads of over three times that of current liner and vessel reinforcement materials” “Equally as important, this revolutionary reinforcement matrix has notably increased resistance to creep, elevated temperatures and cyclic strain based fatigue, which are all an absolute requirement for the long-term efficacy and safety of any hydrogen vessel,” added Li.

In early 2022 BrainDrip executed its first partnership for the manufacturing of an MOF and commercial application of the SG Liner technology. This MOF is scheduled for completion in Q2/2023 and the BrainDrip team will then immediately commence with a multi-mile, mid-diameter natural gas pipeline to hydrogen conversion project.

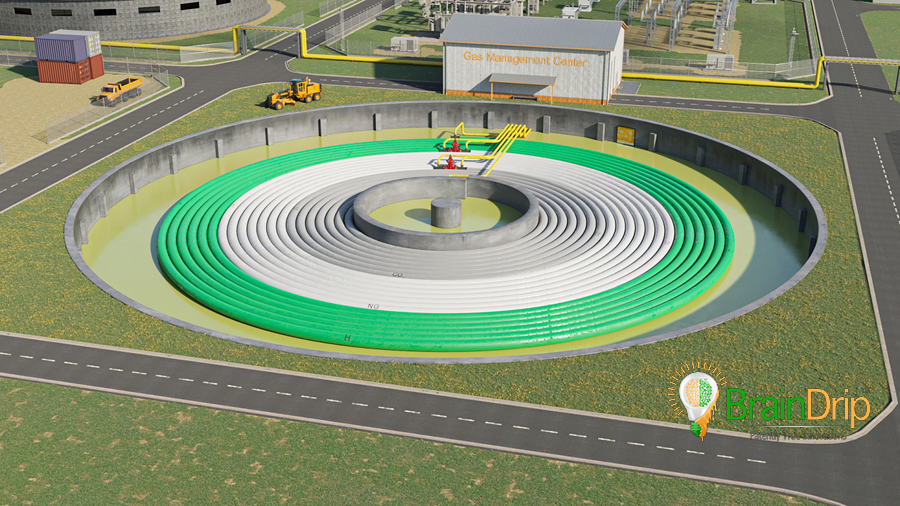

In parallel to the controlled implementation of their SG Liner technology, BrainDrip management continues to move towards sanctioning vertical integration for the commercialization of their disruptive intellectual property development, the SG Coil. The SG coil is a direct adaptation of the novel SG Liner technology for pipelines and utilizes the same Innervated Tubular Structure (ITC). Conversely however, with the SG Coil, the ITC production is facilitated by means of an Autonomous Manufacturing Vehicle (AMV). The AMV adaptation utilizes dynamic production of an auto-attuned ITC synchronously appointed in a coiled coordination for the safe, effectual, high-volume, sub-terra storage of hydrogen and other gaseous commodities.

For hydrogen, the novel design and onsite manufacturing of the SG Coil is scalable to any desired capacity and can provide over 82,000 kg. of storage per level, per sub-terra acre. By comparison, it would require over 100 – 53 ft. storage vessel containers or tube trailers and a surface area of over 11 acres to match the volume of storage of single level, one acre SG Coil. Equally, the novel design affords a continuous vessel with minimal connections, and valving, thus dramatically reducing potential failure points as compared to existing modular methods of storage. The compact nature and high-pressure rating of the coil means that you can store much more fuel, in far less space, much more safely. The ability to segment the coil allows operators to expand their storage as their facility demands change while also providing an additional level of safety. This intrinsic manageability allows operators to convert sections of the coil to different constituents over time. This is especially useful for companies looking to decarbonize, starting with a coil for natural gas and incrementally converting to facilitate their decarbonization transition. Once constructed, the SG gas coil is a low cost and highly effective way to scale the storage of the fuels needed at distributed energy sites while also allowing for the storage of multiple constituents in both high and low-pressure setting, offering the end user greater flexibility. “A true benefit and safety feature of the SG Coil is that it will be most typically installed sub-terra in one or multiple levels thus providing ‘cavern’ like storage with full utilization of the surface area above. This area can be utilized for solar panel arrays, or other renewable solutions therein affording truly net zero storage,” added Weisenberg.

“We see the SG Coil clearly affording industrials, utilities, or power generation stations the ability to store mission critical energy reserves onsite safely and efficiently. In the past storage could only be achieved in areas where the correct geologic conditions existed, installed expensive liquid storage or low volume container vessels. The SG Coil disrupts the entire energy supply chain by affording anyone, anywhere the ability to store large volumes of energy as well as resiliency. This disruptive technology will allow all the energy users the ease of transitioning from coal or natural gas to RNG, hydrogen blends and finally to 100% hydrogen operation without continual and costly upgrades,” stated Wes Cate, President of the Kentucky Oil & Gas Association (KOGA), Board Member of the RNG Coalition and Member of the Kentucky Hydrogen Hub.

The SG Liner and SG Coil Systems are both standalone fully structural innervated tubular composite structures that intrinsically utilize a vast array of continual axially embedded and uninterrupted sensing matrixes paired to AI/ML interrogation systems. These novel embedded systems provide owners and operators with continual encroachment, operational, simulated finite element analysis (FEA) and leak detection data instantaneously, and with pinpoint localization.

In recent months, BrainDrip, LLC has been commissioned to prepare and deliver multiple feasibility studies focused on a variety of localized storage applications for renewable energies utilizing their SG Coil and SG Linear Storage technologies.

Read the most up to date Fuel Cell and Hydrogen Industry news at FuelCellsWorks