- Development of solid oxide fuel cell stack technology applied with press-formed metal separator

- Successfully developed 2kWstackby applying the metal separator module technology manufactured by press molding for the first time in Korea

- The road to mass production is opened to secure price competitiveness and reliability of fuel cell stack

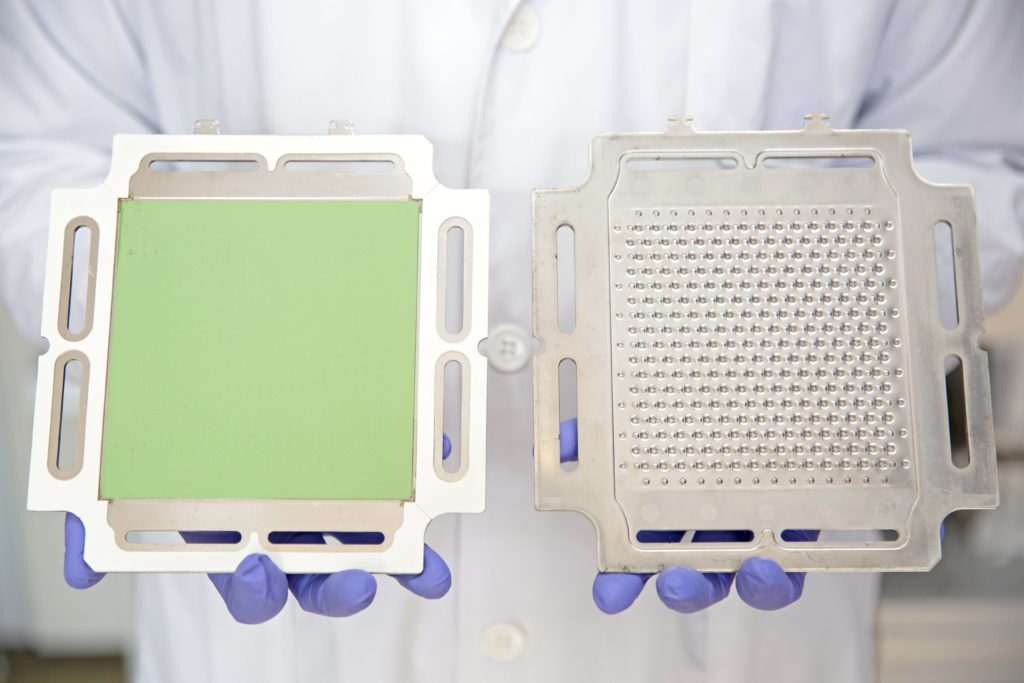

A team led by Dr. Yoo Ji-haeng of the High Temperature Energy Conversion Lab at the Korea Institute of Energy Research has built a 22kW solid oxide fuel cell (SOFC) stack by stacking metal separators and single cell modules layer by layer. Provided by Energy Technology Research Institute

This technology was used by the team of Dr. Yoo Ji-haeng to build a 2kW fuel cell stack and operate it for 200 hours, showing possible commercial use.

This metal separator facilitates electrical contact between dozens of unit cells, and functions as a manifold for supplying fuel and oxygen to each unit cell. Since the metal separator must be built with microchannels to control the flow of fuel and air, it occupies the highest price share along with the unit cell.

Utilizing the metal separator for fuel cell developed by POSCO and the brazing bonding technology of Dongil Brazing, the researchers developed a metal separator. POSCO’s high-temperature fuel cell metal material costs less than one-fifth of the cost of the existing separator material made in Germany.

High-temperature fuel cells available in Korea are usually imported from overseas, but the parts and materials used are domestic. It is noteworthy that they were developed using a separator to which Korean mass-production technology was applied for the first time.

By brazing several metal layers, it was also possible to check component defects in advance during the modularization stage. By doing so, the team explained that it is possible to prevent problems caused by fuel cell stack malfunctions before they occur.

Read the most up to date Fuel Cell and Hydrogen Industry news at FuelCellsWorks