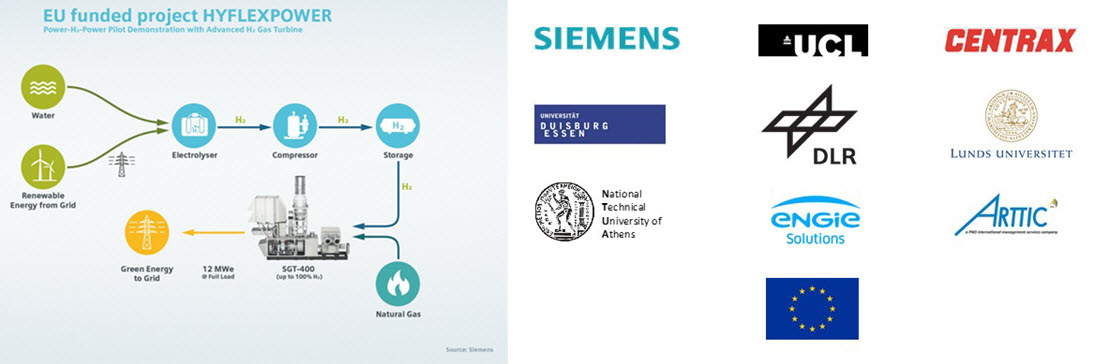

With the HYFLEXPOWER project, a consortium made up of Engie Solutions, Siemens Gas and Power, Centrax, Arttic, German Aerospace Center (DLR) and four European universities are implementing a project funded by the European Commission under the Horizon 2020 Framework Program for Research and Innovation (Grant Agreement 884229).

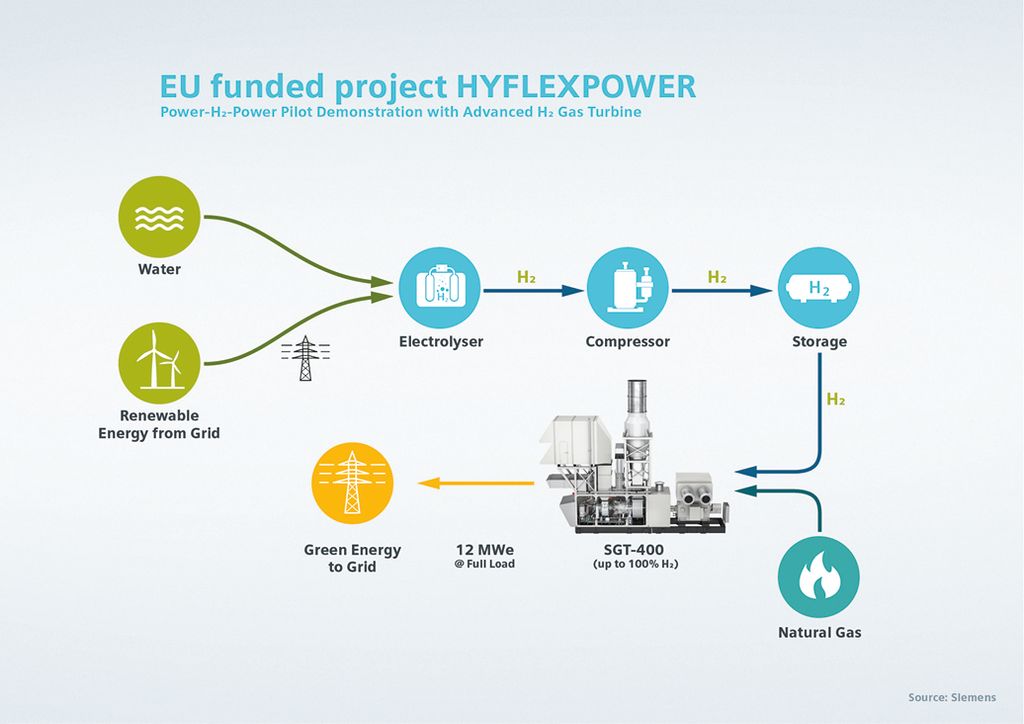

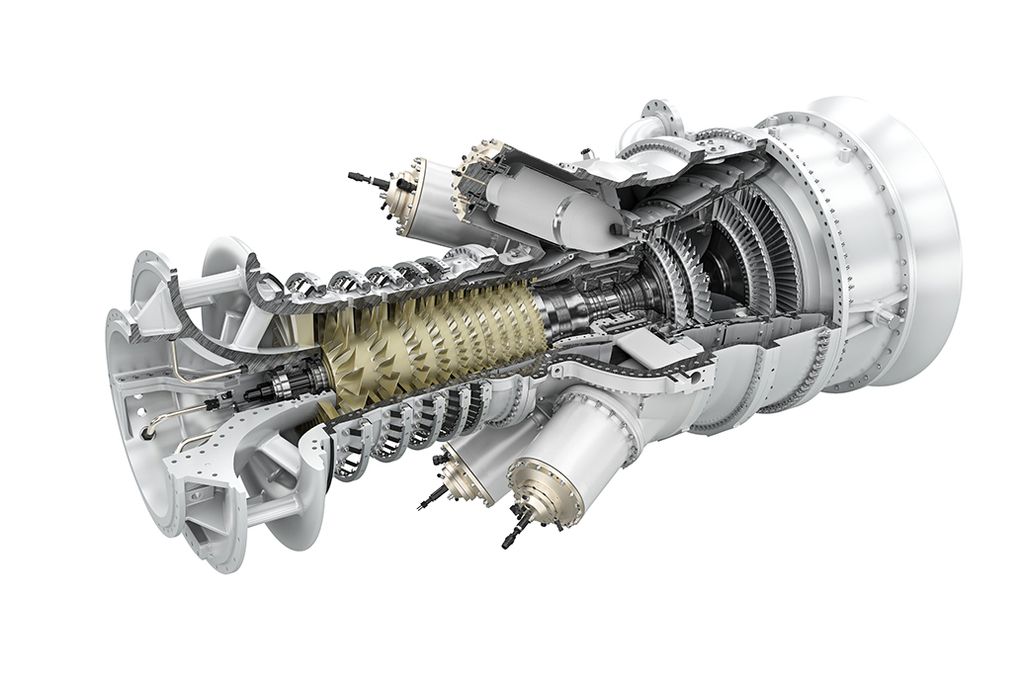

The implementation of this project, the world’s very first industrial-scale power-to-X-to-power1 demonstrator with an advanced hydrogen turbine, will be launched at Smurfit Kappa PRF’s site – a company specialized in manufacturing recycled paper – in Saillat-sur-Vienne, France. The purpose of this project is to prove that hydrogen can be produced and stored from renewable electricity and then added with up to 100 percent to the natural gas currently used with combined heat and power plants. For this an existing Siemens SGT-400 industrial gas turbine will be upgraded to convert stored hydrogen into electricity and thermal energy.

A world’s first: Industrial-scale power-to-X-to-power demonstrator

Through its Horizon 2020 framework program the European Commission supports highly innovative research and demonstration projects aiming at developing and creating innovative products and services and thus stimulating growth in Europe. For this, the European Commission is awarding grants in a competitive procedure in which HYFLEXPOWER was able to assert itself against a large number of competitors.

With this particular project, HYFLEXPOWER will demonstrate that renewable hydrogen can serve as a flexible means of storing energy which can then be used to power a high-power industrial turbine.

Storing fluctuating renewable energy is one of the major challenges of the energy transition. In this context, the stakeholders involved in the HYFLEXPOWER project are developing new technologies that can be used across the whole power-to-X-to-power1 cycle. The installed demonstrator will be used to store excess renewable electricity in the form of green hydrogen. During periods of high demand, this stored green hydrogen will then be used to generate electrical energy to be fed into the grid.

The purpose of HYFLEXPOWER is to prove that hydrogen can be produced and stored from renewable electricity and then added with up to 100 percent to the natural gas currently used with combined heat and power plants.

Engie Solutions has been entrusted with producing energy at the Smurfit Kappa site in Saillat-sur-Vienne, France. At the site, Engie Solutions operates a 12 MWe combined heat and power facility which produces steam for the manufacturing company’s requirements. The conversion of existing infrastructure has the advantage of significantly lower costs and minimized lead time compared to a greenfield site. The project will develop and demonstrate an advanced plant concept that will contribute to modernizing and improving the factory’s existing power plant.

During two demonstration campaigns, the facility will be powered by a mix of natural gas and hydrogen, ultimately aiming for up to 100 percent hydrogen operation. In this regard, the overall goal of the HYFLEXPOWER project is to test an entirely green hydrogen-based power supply for a completely carbon-free energy mix. This would save up to 65,000 tons of CO2 per year for a SGT-400 at baseload operation.

An exclusively European technology

The consortium selected following the call for proposals is made up exclusively of European companies and bodies. Each stakeholder’s role is defined as follows:

- Engie Solutions will build the hydrogen production and storage facility, including the natural gas/hydrogen mixing station prior to the turbine

- Siemens Gas and Power will supply the electrolyser for hydrogen production and develop the hydrogen gas turbine

- Centrax will upgrade the package for hydrogen operation and install the new turbine

- German Aerospace Center (DLR) together with the University College London, University of Duisburg-Essen and Lund University will support the hydrogen turbine technology development

- National Technical University of Athens will perform economic, environmental and social assessments of the concept

- Arttic will support the operational project management and the project’s communication activities.

- May 2020: Contract finalization and start of engineering development.

- 2021: Installation of the hydrogen production, storage and supply facility at pilot demonstration site.

- 2022: Installation of the gas turbine for natural gas/hydrogen mixtures and initial demonstration of advanced pilot plant concept.

- 2023: Pilot demonstration with up to 100 percent hydrogen for carbon-free energy production from stored excess renewable energy.

As part of a consortium, Siemens Energy will upgrade an existing SGT-400 industrial gas turbine to generate electricity and thermal energy with stored hydrogen and demonstrate an industrial-scale power-to-H2-to-power solution.

Siemens Gas and Power helping to increase level of decarbonization

Engie Solutions, a stakeholder committed to hydrogen

Centrax Ltd. developing Hydrogen ready solutions

“Our goal is for our gas turbine combined heat and power systems to be ‘Hydrogen Ready’ to provide future proof power generation solutions for our Customers,” says Harry Trump, Director of Business Development for Centrax Ltd..

1 According to the ADEME (France’s agency for environment and energy management), “Power to X” (or “P2X”) is the act of converting electricity into another energy vector. For the HYFLEXPOWER project, the “X” vector is hydrogen.

www.siemens.com/energy

siemens.com/power-to-x

Read the most up to date Fuel Cell and Hydrogen Industry news at FuelCellsWorks